Quantum Efficiency Tester

PL/EL Integrated System

PV-Reflectumeter

3D Confocal Microscope

In-Line Four Point Probe Tester

Four Point Probe Tester

In-Line Thin Film Thickness Tester

Raman Spectrometer

FTIR Spectrometer

Spectrophotometer

Automatic Spectroscopic Ellipsometer

Contact Resistance Tester

Ultra depth of field 3D microscope

Auto Visual Tester

VMM PV Vision Measuring Machine

Solar Cell Horizontal Tensile Tester

Steady State Solar Simulator for Solar Cell

Solar Cell UV Aging Test Chamber

Solar Cell Comprehensive Tensile Tester

Visual Inspection Tester

Wet Leakage Current Tester

PV Module EL Tester

PV Module UV Preconditioning Chamber

Steady State Solar Simulator for PV Module

Current Continuous Monitor

Potential Induced Degradation Test

Bypass Diode Tester

LeTID Test System

Reverse Current Overload Tester

Impulse Voltage Tester

Hipot Insulation Tester

Ground Continuity Tester

Hipot Insulation Ground Tester

Damp Heat Test Chamber

Humidity Freeze Test

Thermal Cycle Test Chamber

Dynamic Mechanical Load Tester

Static Mechanical Load Tester

Hail Impact Tester

Robustness of Termination Tester

Module Breakage Tester

Cut Susceptibility Tester

Peel Shear Strength Tester

Universal Testing Machine (Single-arm)

Universal Testing Machine (Double-arm)

Glass Transmittance Tester

Acetic Acid Test Chamber

EVA Degree of Crosslinking Test System

Junction Box Comprehensive Tester

Drop ball tester

Semi-automatic scanning four-probe tester

Stylus Profilometer

Maximum Power Point Tracker

Perovskite Glass Transmittance Tester

Perovskite P1 Laser Scribing Multifunctional Testing Machine

Perovskite Online PL Tester

Perovskite Online Sheet Resistance Tester

Online Perovskite Film Thickness Tester

Perovskite Process Inspection Workstation

Portable IV Curve Tester

Portable EL Tester

Portable Thermal Imaging Tester

Solar Module Multi-Channel Testing System

PV Inverter Power Quality Tester

Drone EL Tester

IV Tester

IVEL Cell Sorting Machine

N-TOPCon Half-Cell Front-Side Cutting Process: PL/EL Reveals Phosphorus Diffusion Mechanism to Improve Cutting Yield

Date : 3 September 2025Views : 1355

As the core component of photovoltaic modules, solar cells' manufacturing processes directly impact module power output and reliability. To accommodate flexible voltage/current design and the trend toward larger crystalline silicon cells, cells must be segmented into smaller pieces. Consequently, half-cell technology has become industry-standard, with Thermal Laser Separation (TLS) widely adopted for its low thermal damage and high cutting yield. However, traditional backside cutting may increase leakage points, compromising cell efficiency. This paper investigates the differences between front-side and back-side cutting through comparative experiments. The PL/EL imaging capability of Millennial PL/EL integrated tester reveals the advantages and underlying mechanisms of front-side cutting, providing reference for optimizing the cutting process of N-TOPCon cells.

Experimental Method

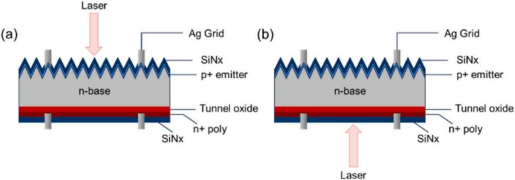

Laser Cutting Orientations: (a) Front-side cutting; (b) Back-side cutting

Using 210 mm × 182 mm N-TOPCon cells, the slotting laser wavelength is 1064 nm with a heating laser diameter of 2.0 mm. Surface morphology is observed via SEM, elemental diffusion is analyzed by EDS, electrical properties are tested through I–V measurements, edge recombination effects are evaluated by photoluminescence (PL), and module quality is verified by electroluminescence (EL).

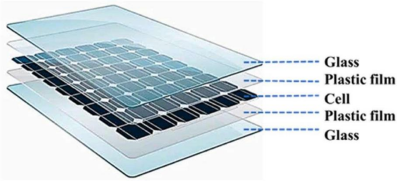

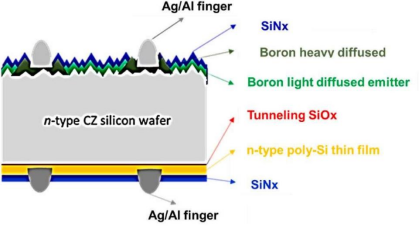

Photovoltaic Module Encapsulation Structure Schematic

Cell and Module I-V Performance

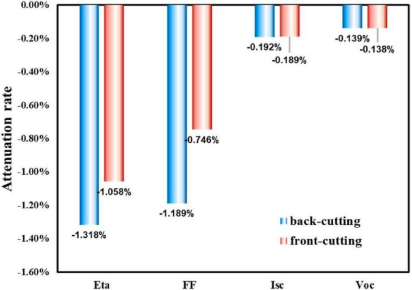

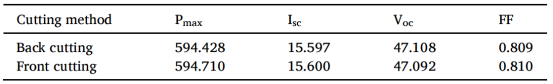

Comparison of I-V Performance Between Front- and Back-Cut Solar Cells

Cell I-V Performance: Parameters such as cell efficiency (Eta) and short-circuit current (Isc) showed slight decreases for both front-cut and back-cut cells. However, the Eta decay rate for back-cut cells was approximately 0.26% higher than that of front-cut cells. This primarily resulted from more significant fill factor (FF) loss in back-cut cells (related to current leakage).

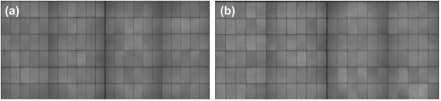

Module Electroluminescence (EL) Images: (a) Backside-cut; (b) Frontside-cut

Comparison of Electrical Performance Parameters Between Front-Cut and Back-Cut Modules

Module I-V Performance: Module testing revealed that front-cut modules exhibited an average power output 0.3W higher than back-cut modules, with no significant differences observed in EL images. Results indicate that the front-cut process outperforms the back-cut process.

Leakage Mechanism Analysis

Groove Morphology (SEM): Front-cut grooves exhibit a width of 1.9 mm, with the heat-affected zone occupying 60% of the cell thickness. Edges appear smooth with no microcracks.

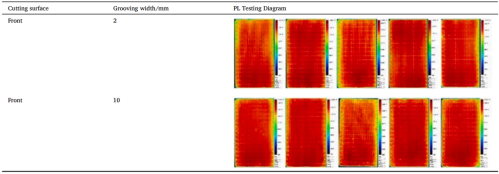

PL Test Results for Front-Cut Batteries (Slot Widths 2mm and 10mm)

Edge Recombination (PL Test): Front-cut edges exhibit brightness consistent with uncut areas, with minimal recombination loss.

Reverse-Bias Leakage Current: Front-cut batteries demonstrate lower leakage current and reduced data dispersion.

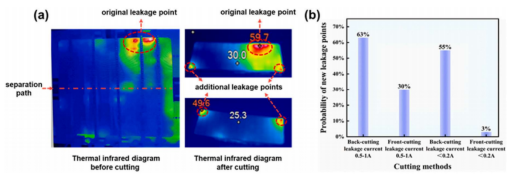

(a) Distribution of new leakage points before and after laser cutting; (b) Statistical probability of new leakage point formation

Probability of Leakage Point Generation:

High-Leakage Cells (0.5–1A): Probability of new leakage point on front side: 30% vs. 63% on back side.

Low-Leakage Cells (<0.2A): Probability on front side: only 3% vs. 12% on back side.

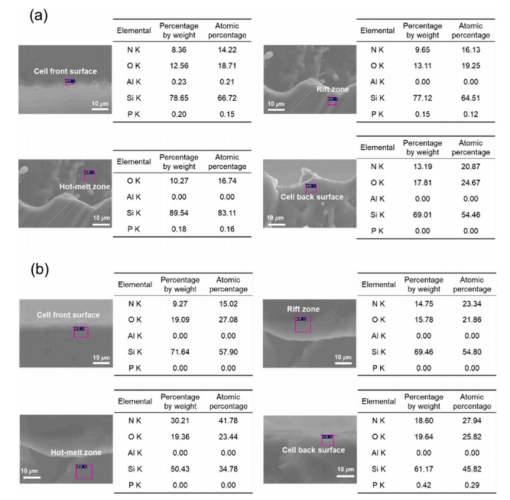

Battery SEM-EDS Images: (a) Back-side cut; (b) Front-side cut

Elemental Diffusion (EDS): Phosphorus (P) detected in the heat-affected zone of the back-side cut (originating from diffusion through the back-side phosphorus-doped layer). The front-side cut shows residual P only at the back-side interface.

Schematic Diagram of N-TOPCon Solar Cell Structure

This study reveals that the core mechanism behind leakage points forming at the trenches on both ends of conventional back-side cut cells lies in phosphorus (P) diffusion. It innovatively proposes a front-side TLS cutting solution. Systematic experiments confirm that front-side cutting significantly reduces reverse-bias leakage current, enhances data convergence and breakdown stability, ultimately achieving a module power gain of approximately 0.3W. This provides technical support for efficient cutting of N-TOPCon cells.

The front-side cutting process for N-TOPCon cells can be directly applied to existing production lines without requiring additional modifications, thereby improving both cell efficiency and cutting yield post-processing.

Millennial PL/EL Integrated Tester

The Millennial PL/EL Integrated Tester simulates sunlight irradiation on perovskite solar cells, uniformly illuminating the entire sample. It captures photoluminescence (PL) signals using specialized lenses to generate PL imaging, and electroluminescence (EL) signals to produce EL imaging. Image algorithms and software process and analyze captured PL/EL images to identify defects, enabling analysis, classification, and summarization based on their characteristics.

email:market@millennialsolar.com

EL/PL imaging, 5 megapixels, with multiple imaging precision modes

Spectral response range: 400nm–1200nm

PL Light Source: Blue light (customizable light source size, wavelength, etc.)

Multiple defect recognition and analysis (pitting, darkening, edge intrusion, etc.) with customizable defect types

The PL/EL imaging technology of the Millennial PL/EL Integrated Tester can verify the causes of differences in front and back cutting processes for N-TOPCon cells at both microscopic and macroscopic levels, providing a feasible technical pathway for enhancing photovoltaic module power output.