Quantum Efficiency Tester

PL/EL Integrated System

PV-Reflectumeter

3D Confocal Microscope

In-Line Four Point Probe Tester

Four Point Probe Tester

In-Line Thin Film Thickness Tester

Raman Spectrometer

FTIR Spectrometer

Spectrophotometer

Automatic Spectroscopic Ellipsometer

Contact Resistance Tester

Ultra depth of field 3D microscope

Auto Visual Tester

VMM PV Vision Measuring Machine

Solar Cell Horizontal Tensile Tester

Steady State Solar Simulator for Solar Cell

Solar Cell UV Aging Test Chamber

Solar Cell Comprehensive Tensile Tester

Visual Inspection Tester

Wet Leakage Current Tester

PV Module EL Tester

PV Module UV Preconditioning Chamber

Steady State Solar Simulator for PV Module

Current Continuous Monitor

Potential Induced Degradation Test

Bypass Diode Tester

LeTID Test System

Reverse Current Overload Tester

Impulse Voltage Tester

Hipot Insulation Tester

Ground Continuity Tester

Hipot Insulation Ground Tester

Damp Heat Test Chamber

Humidity Freeze Test

Thermal Cycle Test Chamber

Dynamic Mechanical Load Tester

Static Mechanical Load Tester

Hail Impact Tester

Robustness of Termination Tester

Module Breakage Tester

Cut Susceptibility Tester

Peel Shear Strength Tester

Universal Testing Machine (Single-arm)

Universal Testing Machine (Double-arm)

Glass Transmittance Tester

Acetic Acid Test Chamber

EVA Degree of Crosslinking Test System

Junction Box Comprehensive Tester

Drop ball tester

Semi-automatic scanning four-probe tester

Stylus Profilometer

Maximum Power Point Tracker

Perovskite Glass Transmittance Tester

Perovskite P1 Laser Scribing Multifunctional Testing Machine

Perovskite Online PL Tester

Perovskite Online Sheet Resistance Tester

Online Perovskite Film Thickness Tester

Perovskite Process Inspection Workstation

Portable IV Curve Tester

Portable EL Tester

Portable Thermal Imaging Tester

Solar Module Multi-Channel Testing System

PV Inverter Power Quality Tester

Drone EL Tester

IV Tester

IVEL Cell Sorting Machine

Study on Outdoor Performance Degradation of Perovskite Cells: Sunlight-Excited Outdoor Photoluminescence and Implied Open-Circuit Voltage iVOC Imaging Technique

Date : 9 September 2025Views : 2015

Perovskite solar cells (PSCs) have achieved laboratory efficiencies exceeding 26%, yet large-area module efficiency maintenance and outdoor long-term stability remain barriers to their application. This study developed an imaging technique based on sunlight-excited outdoor photoluminescence (PL) and implied open-circuit voltage (iVOC), achieving the first quantitative spatial mapping of iVOC for perovskite cells and modules. The high-precision imaging capability of the Millennial Perovskite Online PL Tester enables clear identification of electron defect distributions. By optimizing bandpass filters to enhance signal-to-noise ratio and employing a single BPF calibration method to overcome sample optical property limitations, it achieves iVOC imaging accuracy <5%. This provides a new tool for investigating outdoor performance degradation mechanisms in perovskite cells.

PL Signal Extraction

In outdoor PL imaging, the camera-detected signal Idet comprises ambient light Iamb and PL signal IPL, where Iamb≫IPL.

The study extracts effective PL signals by capturing PL images under open-circuit (OC) and short-circuit (SC) conditions:

Principle: Under OC, Vi peaks → PL peaks; under SC, Vi≈0 → PL≈0, while the constant ambient light component Iamb cancels out.

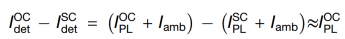

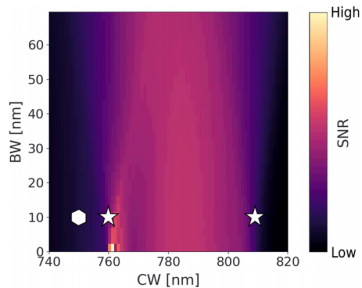

Optical filter optimization

Optical Filter Optimization

Optical Filter Selection

Signal-to-noise ratio (SNR) is dominated by ambient light shot noise. Simulations indicate that for perovskite cells with a bandgap of 1.55 eV, a 10 nm bandwidth BPF centered at 760 nm maximizes SNR due to the absorption valley in the AM1.5G spectrum. Experiments using these parameters achieved PL image resolution approaching indoor levels.

Outdoor PL Imaging of Perovskite Microcells

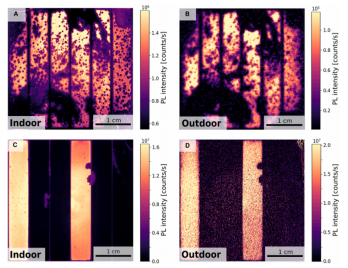

Outdoor PL imaging of perovskite micro-modules (A,C) versus indoor (B,D) PL images

Comparison of indoor/outdoor PL images:

Outdoor images successfully identified localized degradation zones (e.g., active layer defects, non-radiative recombination enhancement regions), showing high consistency with indoor results.

Resolution differences stem from lower outdoor SNR (limited by environmental light shot noise).

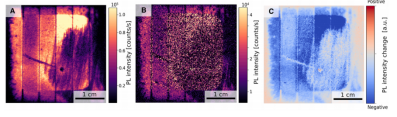

Perovskite Micro-Module Degradation Outdoor PL Imaging (A) PL image before aging, (B) PL image after 2 months of aging, (C) PL intensity decay curve

Two-month outdoor PL tracking of the same component:

Efficiency decreased from 10.3% to 1.7%, with significant PL intensity decay.

Spatial non-uniform decay: Localized regions exhibited more severe Vi decline, suggesting increased contact layer resistance or charge collection loss.

PL images correlate fill factor decay (via spatial distribution of shunt resistance) with short-circuit current loss (active layer degradation).

iVOC Imaging Method

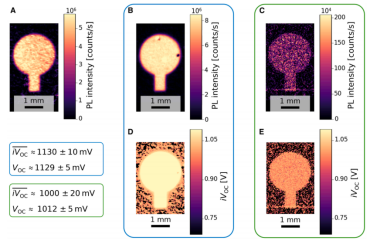

Outdoor iVOC imaging of PSCs: (A) PL image of reference PSC for calibration; (B, C) PL images of two PSCs under test; (D, E) corresponding iVOC images

Traditional calibration requires optical properties matching between samples and reference cells. This study employs a simplified single-BPF calibration method using a BPF with a 750 nm center wavelength and 10 nm bandwidth. It detects only the high-energy tail region of the PL spectrum—where PL intensity is insensitive to optical characteristics. This approach negates optical differences between calibration and test cells, controlling iVOC error within 5 mV.

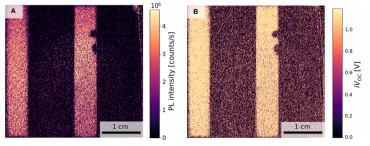

Outdoor iVoc Imaging of Perovskite Micro-Modules: (A) PL Image, (B) iVoc Image

For the first time, outdoor iVOC images of perovskite micro-modules were obtained. The module-level iVOC (3.5±0.5 V) aligns with the measured Voc (3.48±0.05 V).

This paper presents a novel method for capturing outdoor PL images of PSCs and perovskite modules using sunlight as the sole excitation source. This approach has been demonstrated to yield high-quality images revealing spatial information about PSC quality uniformity and the presence of various electronic defects, as validated by PL images obtained using an indoor laboratory PL imaging system. Beyond qualitative PL insights, we demonstrate that a single BPF method can be employed to calibrate PL signals into iVOC images. These iVOC distributions correlate with overall device performance and provide spatially resolved information on varying defect severities.

Millennial Perovskite Online PL Tester

email:market@millennialsolar.com

Online PL defect detection systematically addresses core challenges in solar cell production—speed, yield, cost, process optimization, and stability—through non-contact, high-precision, real-time feedback. Combined with AI deep learning, it enables fully automated defect identification and process feedback.

High-Precision PL Imaging: Utilizes line-scan laser with imaging accuracy <50μm/pixel (customizable)

High-Speed Online PL Defect Detection: Detection speed ≤2s, miss rate <0.1%; misclassification rate <0.3%

AI Defect Classification Training: Enables fully automated defect recognition and process feedback

Millennial perovskite online PL tester leverages high-precision PL imaging, high-speed inline detection, and AI defect recognition to enable rapid defect identification and process feedback during production. This not only provides comprehensive data support for optimizing perovskite cell performance but also accelerates its industrialization process.