Quantum Efficiency Tester

PL/EL Integrated System

PV-Reflectumeter

3D Confocal Microscope

In-Line Four Point Probe Tester

Four Point Probe Tester

In-Line Thin Film Thickness Tester

Raman Spectrometer

FTIR Spectrometer

Spectrophotometer

Automatic Spectroscopic Ellipsometer

Contact Resistance Tester

Ultra depth of field 3D microscope

Auto Visual Tester

VMM PV Vision Measuring Machine

Solar Cell Horizontal Tensile Tester

Steady State Solar Simulator for Solar Cell

Solar Cell UV Aging Test Chamber

Solar Cell Comprehensive Tensile Tester

Visual Inspection Tester

Wet Leakage Current Tester

PV Module EL Tester

PV Module UV Preconditioning Chamber

Steady State Solar Simulator for PV Module

Current Continuous Monitor

Potential Induced Degradation Test

Bypass Diode Tester

LeTID Test System

Reverse Current Overload Tester

Impulse Voltage Tester

Hipot Insulation Tester

Ground Continuity Tester

Hipot Insulation Ground Tester

Damp Heat Test Chamber

Humidity Freeze Test

Thermal Cycle Test Chamber

Dynamic Mechanical Load Tester

Static Mechanical Load Tester

Hail Impact Tester

Robustness of Termination Tester

Module Breakage Tester

Cut Susceptibility Tester

Peel Shear Strength Tester

Universal Testing Machine (Single-arm)

Universal Testing Machine (Double-arm)

Glass Transmittance Tester

Acetic Acid Test Chamber

EVA Degree of Crosslinking Test System

Junction Box Comprehensive Tester

Drop ball tester

Semi-automatic scanning four-probe tester

Stylus Profilometer

Maximum Power Point Tracker

Perovskite Glass Transmittance Tester

Perovskite P1 Laser Scribing Multifunctional Testing Machine

Perovskite Online PL Tester

Perovskite Online Sheet Resistance Tester

Online Perovskite Film Thickness Tester

Perovskite Process Inspection Workstation

Portable IV Curve Tester

Portable EL Tester

Portable Thermal Imaging Tester

Solar Module Multi-Channel Testing System

PV Inverter Power Quality Tester

Drone EL Tester

IV Tester

IVEL Cell Sorting Machine

Primary Materials and Manufacturing Processes for Photovoltaic Modules

Date : 12 September 2025Views : 1275

Photovoltaic modules, also known as solar panels, consist of multiple solar cells of identical size and quantity. Within photovoltaic systems, these modules typically comprise silicon wafers, glass, EVA laminate, and backsheets. Silicon wafers serve as the core material of photovoltaic modules, accounting for approximately 90% of the total module cost, thus demanding high quality standards. Glass and EVA film each contribute about 10% to the total cost, significantly impacting the module's performance and lifespan.

Photovoltaic modules find extensive applications across various sectors, including residential lighting, electric vehicles, communication base stations, and solar-powered agricultural greenhouses.

Primary Materials of Photovoltaic Modules

Solar Cells

The core component of photovoltaic modules, typically made from high-purity monocrystalline or polycrystalline silicon. Through processes like doping and junction formation, they create PN junctions responsible for converting solar energy into electricity.

Tin-Coated Copper Ribbon (Photovoltaic Busbar)

Used to connect solar cells, serving as a conductor and current collector.

EVA

A copolymer of ethylene and vinyl acetate, serving as the encapsulation film. It bonds the cell, glass, and backsheet while protecting the cell's electrical properties.

Backsheet

Protects the rear surface of the PV module against environmental corrosion, such as humidity and heat, while enhancing light absorption efficiency and insulation performance.

Tempered Glass

Serves as the structural support for photovoltaic modules, enhancing load-bearing capacity while offering high light transmittance and effective water/gas barrier properties.

Silicone Sealant

Used for bonding and sealing photovoltaic modules, enhancing UV resistance.

Aluminum Alloy Frame

Protects the glass edges, enhances the module's sealing performance and mechanical strength, and facilitates installation and transportation.

Junction Box

Contains the connectors for the solar panel, used to direct electrical energy to external devices.

These materials collectively form the fundamental architecture of photovoltaic modules, ensuring the efficient operation and long-term stability of solar panels.

Analysis of Photovoltaic Module Manufacturing Process Steps

Silicon Wafer Preparation

The core material for photovoltaic modules is silicon wafers, which include both monocrystalline and polycrystalline silicon.

Cell Fabrication

Silicon wafers undergo processing into photovoltaic cells through foundational steps including cleaning, cutting, etching, diffusion, and deposition. The critical step is the diffusion process, which forms the PN junction structure.

Module Encapsulation

Pre-treated stacked layers undergo surface impurity removal and interlayer adhesion inspection; then sent to a laminator where EVA adhesive film melts under high temperature (approx. 130-150°C) and pressure, fully filling gaps and bonding layers. After lamination, modules enter a curing oven for temperature stabilization, allowing EVA to fully cross-link and solidify into a stable monolithic structure while ensuring sealing integrity and weather resistance.

Cell Testing and Sorting

Classify cells based on performance parameters to optimize utilization rates.

Front Side Soldering

Solder busbars (tin-plated copper strips) to the front main grid lines of each cell, preparing for series connection.

Back Side Series Connection

Use a soldering iron and solder wire to sequentially connect cells in series, forming module strings, and solder lead wires.

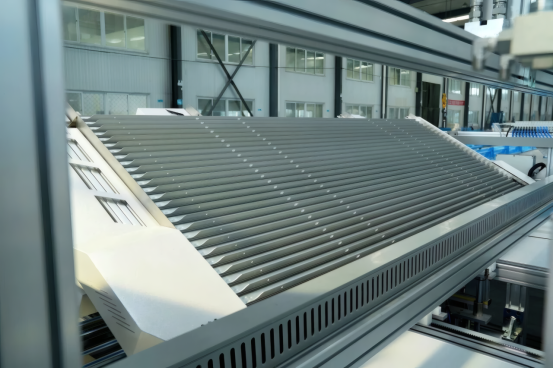

Lamination Layup

Arrange the strung cells, glass, EVA, glass fiber, and backsheet in specific layers for lamination preparation.

Framing and Inspection

After trimming and framing (including junction box installation), inspect the solar module for anomalies like microcracks, fragments, cold solder joints, or open circuits. Conduct power and visual tests; ship only qualified modules.

These process steps ensure the quality and performance of photovoltaic modules, enabling efficient conversion of solar energy into electricity.