Quantum Efficiency Tester

PL/EL Integrated System

PV-Reflectumeter

3D Confocal Microscope

In-Line Four Point Probe Tester

Four Point Probe Tester

In-Line Thin Film Thickness Tester

Raman Spectrometer

FTIR Spectrometer

Spectrophotometer

Automatic Spectroscopic Ellipsometer

Contact Resistance Tester

Ultra depth of field 3D microscope

Auto Visual Tester

VMM PV Vision Measuring Machine

Solar Cell Horizontal Tensile Tester

Steady State Solar Simulator for Solar Cell

Solar Cell UV Aging Test Chamber

Solar Cell Comprehensive Tensile Tester

Visual Inspection Tester

Wet Leakage Current Tester

PV Module EL Tester

PV Module UV Preconditioning Chamber

Steady State Solar Simulator for PV Module

Current Continuous Monitor

Potential Induced Degradation Test

Bypass Diode Tester

LeTID Test System

Reverse Current Overload Tester

Impulse Voltage Tester

Hipot Insulation Tester

Ground Continuity Tester

Hipot Insulation Ground Tester

Damp Heat Test Chamber

Humidity Freeze Test

Thermal Cycle Test Chamber

Dynamic Mechanical Load Tester

Static Mechanical Load Tester

Hail Impact Tester

Robustness of Termination Tester

Module Breakage Tester

Cut Susceptibility Tester

Peel Shear Strength Tester

Universal Testing Machine (Single-arm)

Universal Testing Machine (Double-arm)

Glass Transmittance Tester

Acetic Acid Test Chamber

EVA Degree of Crosslinking Test System

Junction Box Comprehensive Tester

Drop ball tester

Semi-automatic scanning four-probe tester

Stylus Profilometer

Maximum Power Point Tracker

Perovskite Glass Transmittance Tester

Perovskite P1 Laser Scribing Multifunctional Testing Machine

Perovskite Online PL Tester

Perovskite Online Sheet Resistance Tester

Online Perovskite Film Thickness Tester

Perovskite Process Inspection Workstation

Portable IV Curve Tester

Portable EL Tester

Portable Thermal Imaging Tester

Solar Module Multi-Channel Testing System

PV Inverter Power Quality Tester

Drone EL Tester

IV Tester

IVEL Cell Sorting Machine

Reliability Testing of Crystalline Silicon Pv Modules—PID Testing

Date : 24 September 2025Views : 1135

Crystalline silicon Pv Modules are power-generating devices installed outdoors that require full exposure to solar radiation to produce electricity. Due to various environmental factors, modules inevitably endure exposure to dust, salt spray, strong winds, rain, snow, hail, humid heat, dry cold, condensation and evaporation of water vapor, atmospheric gas pollution, seasonal temperature fluctuations across spring, summer, autumn, and winter, and intense ultraviolet radiation. They must maintain stable and effective power generation performance for 25 years or longer. Therefore, assessing Pv Module reliability is a particularly critical concern. The following analysis focuses on Potential Induced Degradation (PID) testing.

I. What is PID?

PID testing evaluates potential induced degradation.

Polarization, electrolytic corrosion, and electrochemical corrosion. When modules operate under high voltage for extended periods, leakage currents occur between the cover glass, encapsulation materials, and frame. This causes significant charge accumulation on the cell surface, degrading the passivation effect. Consequently, the fill factor, short-circuit current, and open-circuit voltage decrease, resulting in module performance below design standards. The purpose of PID testing is to verify a module's ability to withstand performance changes under high-intensity voltage conditions.

II. Three Modes of PID Degradation

1. Current diversion at the p-n junction within the solar cell: When a negative voltage is applied across the cell and a positive voltage to the frame (i.e., when the Pv Module is subjected to negative bias), leaking anode ions flow into the cell. Impurities within the semiconductor form conductive pathways inside the cell, reducing its parallel resistance.

2. Moisture readily penetrates the edges of modules. When EVA undergoes hydrolysis, it produces acetic acid. This acetic acid reacts with Na⁺ ions in the glass, generating large quantities of freely mobile Na⁺ ions. Sodium ions on the glass surface migrate through the encapsulation material to the cell surface, where they undergo electrochemical corrosion reactions with the silver grid lines on the cell surface. This corrodes the grid lines, leading to low fill factor, high series resistance, and module performance degradation. This type of degradation is irreversible. POE, being a non-polar molecule with saturated bonds, is resistant to hydrolysis and exhibits low water vapor permeability. Its high volume resistivity significantly impedes the migration rate of positive charge ions (e.g., Na+) toward the cell surface, thereby mitigating PID to a certain extent.

3. This refers to long-term operation of the module under high voltage, where leakage currents exist between the cover glass, encapsulation materials, and frame. Substantial charge accumulation on the cell surface creates an electric field opposite to the passivation field, degrading the passivation effect on the cell surface. This polarization effect reduces the fill factor, short-circuit current, and open-circuit voltage, causing the module performance to fall below design standards. However, this degradation is reversible.

EL Characteristics of PID Failure

EL Image of Bifacial Module Before PID Testing

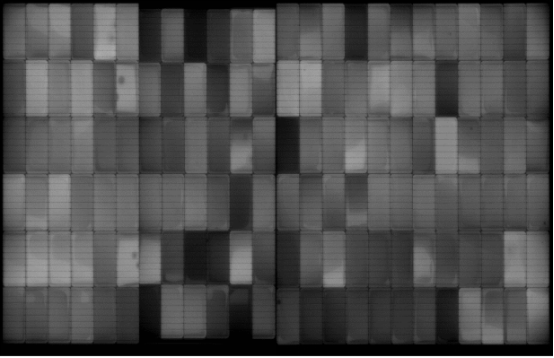

EL Image of Bifacial Module After PID Testing

The outer perimeter shows significant darkening after PID testing compared to before testing. This occurs because voltage is applied to the frame, and cells closer to the frame experience greater potential, leading to more severe PID.

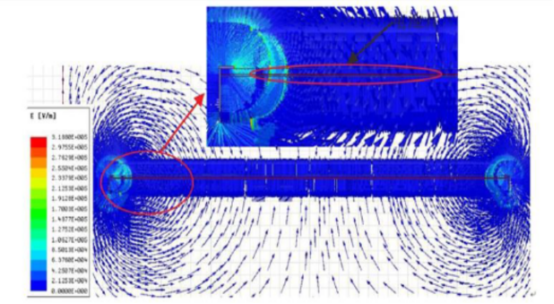

Distribution and Magnitude of the Strong Electric Field Formed by the Metal Frame on the Solar Cell Under Bias

The closer to the frame, the higher the electric field strength and the greater the potential.

III. Factors Affecting PID Degradation

Cell Variation

Impact of Module Encapsulation Materials

Inverter Influence

Environmental Factors

IV. PID Prevention and Solutions

Cell Impact: The refractive index of the cell's anti-reflective coating affects the module's PID resistance. By optimizing the passivation layer on the cell surface and enhancing the density of SiN₄, a more compact protective layer can be formed while maintaining efficiency. This approach improves PID performance.

Module Encapsulation Material Impact: Reducing leakage current pathways, selecting glass with low sodium ion content, opting for transparent backsheets, employing high-barrier POE, and using adhesives with superior sealing properties are effective approaches to prevent PID occurrence. Transparent backsheets primarily address PID issues in P-PERC modules, where the N-type PN junction is located on the front surface. The N-type PN junction area is significantly affected, and protection for N-type modules relies heavily on encapsulation materials. High-barrier POE is one effective solution.

Inverter Influence: When both the inverter's negative output terminal and the modules are under negative bias conditions, the effect becomes more pronounced as the distance between the modules and the inverter's negative output terminal decreases. If both the inverter's positive output terminal and the modules are under positive bias conditions, the position of the Pv Modules does not affect PID, and the PID phenomenon is not significant under these conditions. For PID caused by system factors, grounding the negative output terminals of both the modules and the inverter can mitigate the effect.

Environmental Factors: As ambient temperature increases, the reverse saturation current within the cells rises sharply, causing leakage current to grow rapidly and exacerbating PID. Thus, higher ambient temperatures lead to more pronounced PID.

The PID effect in Pv Modules intensifies with rising temperature, humidity, and bias voltage, leading to decreased output power and reduced project-level electricity generation. To mitigate PID at the module level, it is crucial to increase the insulation resistance between external circuits and internal cells, reduce leakage current, and select encapsulation materials with excellent insulation properties. This approach fundamentally prevents the occurrence of PID.

Related Solutions

HJT Solar Cell

Optimized HJT cell efficiency through tested structures and key process analysis.

View DetailsRelated Products