Quantum Efficiency Tester

PL/EL Integrated System

PV-Reflectumeter

3D Confocal Microscope

In-Line Four Point Probe Tester

Four Point Probe Tester

In-Line Thin Film Thickness Tester

Raman Spectrometer

FTIR Spectrometer

Spectrophotometer

Automatic Spectroscopic Ellipsometer

Contact Resistance Tester

Ultra depth of field 3D microscope

Auto Visual Tester

VMM PV Vision Measuring Machine

Solar Cell Horizontal Tensile Tester

Steady State Solar Simulator for Solar Cell

Solar Cell UV Aging Test Chamber

Solar Cell Comprehensive Tensile Tester

Visual Inspection Tester

Wet Leakage Current Tester

PV Module EL Tester

PV Module UV Preconditioning Chamber

Steady State Solar Simulator for PV Module

Current Continuous Monitor

Potential Induced Degradation Test

Bypass Diode Tester

LeTID Test System

Reverse Current Overload Tester

Impulse Voltage Tester

Hipot Insulation Tester

Ground Continuity Tester

Hipot Insulation Ground Tester

Damp Heat Test Chamber

Humidity Freeze Test

Thermal Cycle Test Chamber

Dynamic Mechanical Load Tester

Static Mechanical Load Tester

Hail Impact Tester

Robustness of Termination Tester

Module Breakage Tester

Cut Susceptibility Tester

Peel Shear Strength Tester

Universal Testing Machine (Single-arm)

Universal Testing Machine (Double-arm)

Glass Transmittance Tester

Acetic Acid Test Chamber

EVA Degree of Crosslinking Test System

Junction Box Comprehensive Tester

Drop ball tester

Semi-automatic scanning four-probe tester

Stylus Profilometer

Maximum Power Point Tracker

Perovskite Glass Transmittance Tester

Perovskite P1 Laser Scribing Multifunctional Testing Machine

Perovskite Online PL Tester

Perovskite Online Sheet Resistance Tester

Online Perovskite Film Thickness Tester

Perovskite Process Inspection Workstation

Portable IV Curve Tester

Portable EL Tester

Portable Thermal Imaging Tester

Solar Module Multi-Channel Testing System

PV Inverter Power Quality Tester

Drone EL Tester

IV Tester

IVEL Cell Sorting Machine

Bypass Diodes in Solar Panels

Date : 7 November 2025Views : 690

Various issues may arise during the operation of Solar Panels in power plants, leading to a loss of power generation. One such issue is the breakdown of bypass diodes in junction boxes. Below is a brief introduction to bypass diodes in Solar Panels.

I. Bypass Diodes for Solar Panels

The commonly used bypass diodes in Solar Panels are electronically termed Schottky diodes. Named after their inventor, Dr. Schottky, SBD stands for Schottky Barrier Diode. Unlike PN junction diodes formed by contacting P-type and N-type semiconductors, SBDs are fabricated using the metal-semiconductor junction principle, where a metal (e.g., gold, silver, platinum) contacts a semiconductor.

II. Structure of the Schottky Diode

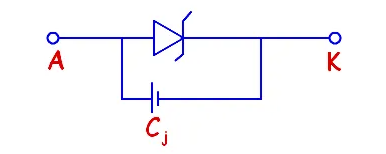

Equivalent Circuit of a Schottky Diode

A Schottky diode is formed by connecting a doped semiconductor region (typically N-type) to a metal (such as gold, silver, or platinum). It features a metal-semiconductor junction rather than a PN junction, as illustrated below.

Equivalent Circuit of a Schottky Diode

Because a Schottky diode involves metal-semiconductor contact, it lacks the charge storage mechanism present in PN diodes. When switching the electric field, there is no delay caused by the need to first dissipate stored charge. Consequently, Schottky diodes exhibit extremely fast switching response times. This is one of the key reasons they are selected as bypass diodes. When hot spots occur in solar cells, high currents can be instantly bypassed, providing the fastest protection. Once the hot spot disappears, the bypass diode immediately returns to its cutoff state, allowing the module to resume maximum power output. Thus, the ultra-high switching response frequency of Schottky diodes precisely meets the application requirements of solar modules.

III. Operating Principle of Bypass Diodes

Bypass diodes are typically connected in parallel with two series strings of solar cells. When a cell or a string becomes shaded, the shaded cells cease to generate electricity and instead act as resistive loads. As the resistance increases to a certain threshold, the corresponding bypass diode activates. This bypasses the shaded string, The module current then flows through the bypass diode, preventing excessive heat generation caused by current flowing through the shaded cells and ensuring the module's normal operation.

IV. Failure of Bypass Diodes

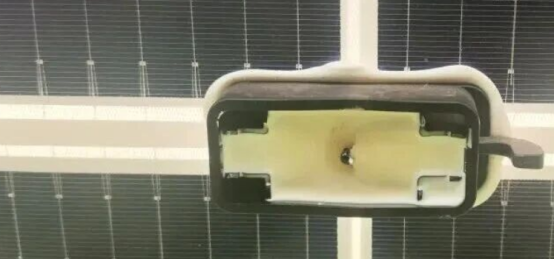

Failure of the bypass diode

Common failure modes for bypass diodes include inability to withstand high temperatures and high current surges. When partial shading triggers the bypass diode to conduct, the high forward current causes rapid heating. Under other adverse conditions—such as loose solder joints in the junction box or prolonged operation of the diode—breakdown is likely to occur.

① Poor Soldering: Weak connections exist at the junction between the diode leads and copper conductors within the junction box, as well as between the busbar and copper conductors. When shading or other issues activate the bypass diode, these solder joints overheat. If the accumulated heat exceeds the thermal deformation temperature of the junction box insulation material, the box will age and deform. The longer the bypass diodes remain activated, the greater the risk of junction box deformation and aging. When temperatures exceed the upper limit of the diode junction temperature, the high heat can cause thermal breakdown and damage to the bypass diodes, potentially even burning out the junction box.

② Hot Spots: Under prolonged conditions such as shading, microcracks, or localized hot spots, the bypass diode remains in continuous operation. This causes the junction temperature to rise. Once the accumulated junction temperature reaches a critical level, the bypass diode undergoes thermal breakdown and fails. If not addressed promptly, heat accumulation may reach the deformation temperature of the junction box insulation material, causing deformation and aging. In severe cases, this can lead to junction box burnout.

③ Lightning Strikes: When a PV module is struck by lightning, improper or non-compliant grounding can cause the bypass diode to instantly break down under high voltage. After the storm clears, as normal module current flows through the failed diode over time, the diode generates heat. Once heat accumulates to a certain level, it can cause the junction box to age and deform, or even burn out. (Lightning strikes typically leave impact marks on the module frame)

V. Testing Standards for Bypass Diodes

① GB/T 44081—2024/IEC 62979:2017 “Thermal Runaway Testing for Bypass Diodes in Solar Panels”

② IEC 61215-2:2021 “Functional Testing and Thermal Performance Testing of Bypass Diodes”