Quantum Efficiency Tester

PL/EL Integrated System

PV-Reflectumeter

3D Confocal Microscope

In-Line Four Point Probe Tester

Four Point Probe Tester

In-Line Thin Film Thickness Tester

Raman Spectrometer

FTIR Spectrometer

Spectrophotometer

Automatic Spectroscopic Ellipsometer

Contact Resistance Tester

Ultra depth of field 3D microscope

Auto Visual Tester

VMM PV Vision Measuring Machine

Solar Cell Horizontal Tensile Tester

Steady State Solar Simulator for Solar Cell

Solar Cell UV Aging Test Chamber

Solar Cell Comprehensive Tensile Tester

Visual Inspection Tester

Wet Leakage Current Tester

PV Module EL Tester

PV Module UV Preconditioning Chamber

Steady State Solar Simulator for PV Module

Current Continuous Monitor

Potential Induced Degradation Test

Bypass Diode Tester

LeTID Test System

Reverse Current Overload Tester

Impulse Voltage Tester

Hipot Insulation Tester

Ground Continuity Tester

Hipot Insulation Ground Tester

Damp Heat Test Chamber

Humidity Freeze Test

Thermal Cycle Test Chamber

Dynamic Mechanical Load Tester

Static Mechanical Load Tester

Hail Impact Tester

Robustness of Termination Tester

Module Breakage Tester

Cut Susceptibility Tester

Peel Shear Strength Tester

Universal Testing Machine (Single-arm)

Universal Testing Machine (Double-arm)

Glass Transmittance Tester

Acetic Acid Test Chamber

EVA Degree of Crosslinking Test System

Junction Box Comprehensive Tester

Drop ball tester

Semi-automatic scanning four-probe tester

Stylus Profilometer

Maximum Power Point Tracker

Perovskite Glass Transmittance Tester

Perovskite P1 Laser Scribing Multifunctional Testing Machine

Perovskite Online PL Tester

Perovskite Online Sheet Resistance Tester

Online Perovskite Film Thickness Tester

Perovskite Process Inspection Workstation

Portable IV Curve Tester

Portable EL Tester

Portable Thermal Imaging Tester

Solar Module Multi-Channel Testing System

PV Inverter Power Quality Tester

Drone EL Tester

IV Tester

IVEL Cell Sorting Machine

Troubleshooting Air Bubbles in Laminated Solar panels

Date : 14 November 2025Views : 465

Air bubbles appearing in laminated Solar panels may result from multiple factors including raw materials, equipment, process parameters, environmental conditions, and operator practices. Below are specific cause analyses and solutions.

I. Material Anomalies

Positioning Tape Bubbles

Positioning Tape Bubbles

① Positioning Tape Bubbles: Bubbles in positioning tape after lamination typically result from mismatched lamination parameters (primarily temperature and pressure) with the tape. This can be resolved by adjusting lamination parameters or replacing the positioning tape. (The author recommends replacing the tape, as adjusting temperature and pressure usually requires subsequent crosslinking degree and tensile strength testing, which is cumbersome.)

② Film Anomalies: Film bubbles usually stem from “dead material” within the film, localized adhesive deficiency, or low basis weight. “Dead material” bubbles are typically small and contain a white dot matching the film's raw material color.

Bubbles from localized film defects often reveal the embossed pattern from the glass substrate. When appearing on the front side of the cell, the cell may exhibit its natural blue color instead of black. Material defects can be resolved by replacing the material. If the cause cannot be definitively attributed to the material, cross-verification through material replacement can help identify the problematic material.

II. Equipment Abnormalities

Localized Temperature Anomaly Electrical Bubble

① Air Leakage: After the laminator closes its lid, air leakage may occur, leading to bubbles. The cause of bubble formation is localized air leakage around the chamber during vacuum extraction. Air enters the chamber through these leaks, resulting in insufficient vacuum pressure at those points and preventing bubbles from being fully extracted from the module. (Leaks vary in severity. Minor leaks typically produce bubbles along the module edges, especially on the short sides or corresponding long sides aligned with the laminator's head/tail positions. Major leaks trigger vacuum failure alerts, preventing proper vacuuming.)

To address air leaks, inspect the laminator's sealing rings, vacuum pump, vacuum lines, and other components. Also verify that the cover is fully closed and no foreign objects are obstructing the sealing ring or upper chamber flange after closure.

② Temperature: When lamination parameters are correct but non-snowflake-pattern bubbles appear on the front side (the side closest to the substrate during lamination) at a fixed position on a stationary laminator, consider whether localized overheating at the laminator's heating bottom causes premature cross-linking of the adhesive film at that spot. Use a spot thermometer to check temperatures and implement localized temperature compensation to resolve the issue.

Bubbles caused by localized temperature anomalies appear smoother compared to snowflake-pattern bubbles. They typically manifest as multiple small, relatively dense bubbles in a fixed position on the laminator at a fixed location.

III. Personnel Operations

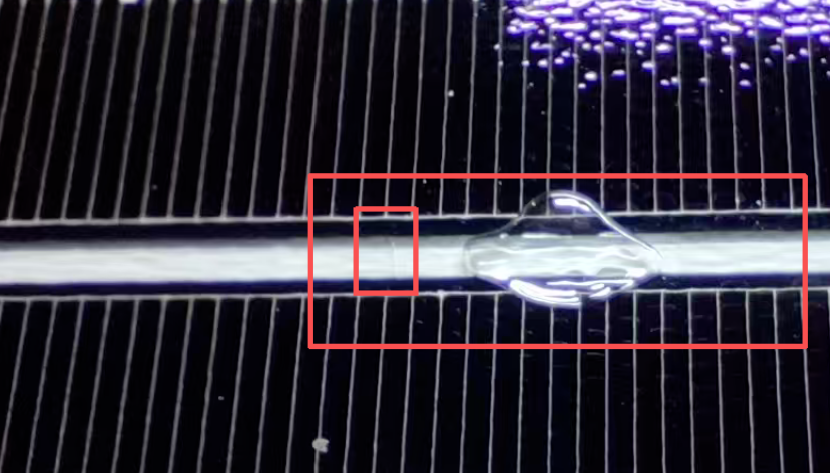

Bubbles formed when water splashes onto the plastic film

① Improper Film Application: During film placement, incorrect parameter settings by operators may result in insufficient film coverage, misaligned film positioning, missing edge strips, or excessively narrow application. This causes adhesive deficiency at module edges, leading to bubbles after lamination. Pre-EL inspection can confirm whether film application is the cause.

② Water Spillage on Film/Glass: Occasionally, water spilled onto the film or glass during cleaning or other operations can cause bubbles after lamination.

These bubbles exhibit a distinct water-sprayed appearance, differing entirely from bubbles caused by air leaks, film placement errors, or temperature anomalies.

IV. Environmental Issues

① High moisture content in film: When stored for extended periods in high-humidity environments, the film absorbs moisture. This leads to bubbles during lamination, appearing as small, randomly distributed air pockets.

③ Foreign object bubbles: Bubbles caused by foreign objects like insects result from substandard workshop conditions. This can be addressed by ensuring workshop personnel close doors promptly and implementing insect prevention measures.