Quantum Efficiency Tester

PL/EL Integrated System

PV-Reflectumeter

3D Confocal Microscope

In-Line Four Point Probe Tester

Four Point Probe Tester

In-Line Thin Film Thickness Tester

Raman Spectrometer

FTIR Spectrometer

Spectrophotometer

Automatic Spectroscopic Ellipsometer

Contact Resistance Tester

Ultra depth of field 3D microscope

Auto Visual Tester

VMM PV Vision Measuring Machine

Solar Cell Horizontal Tensile Tester

Steady State Solar Simulator for Solar Cell

Solar Cell UV Aging Test Chamber

Solar Cell Comprehensive Tensile Tester

Visual Inspection Tester

Wet Leakage Current Tester

PV Module EL Tester

PV Module UV Preconditioning Chamber

Steady State Solar Simulator for PV Module

Current Continuous Monitor

Potential Induced Degradation Test

Bypass Diode Tester

LeTID Test System

Reverse Current Overload Tester

Impulse Voltage Tester

Hipot Insulation Tester

Ground Continuity Tester

Hipot Insulation Ground Tester

Damp Heat Test Chamber

Humidity Freeze Test

Thermal Cycle Test Chamber

Dynamic Mechanical Load Tester

Static Mechanical Load Tester

Hail Impact Tester

Robustness of Termination Tester

Module Breakage Tester

Cut Susceptibility Tester

Peel Shear Strength Tester

Universal Testing Machine (Single-arm)

Universal Testing Machine (Double-arm)

Glass Transmittance Tester

Acetic Acid Test Chamber

EVA Degree of Crosslinking Test System

Junction Box Comprehensive Tester

Drop ball tester

Semi-automatic scanning four-probe tester

Stylus Profilometer

Maximum Power Point Tracker

Perovskite Glass Transmittance Tester

Perovskite P1 Laser Scribing Multifunctional Testing Machine

Perovskite Online PL Tester

Perovskite Online Sheet Resistance Tester

Online Perovskite Film Thickness Tester

Perovskite Process Inspection Workstation

Portable IV Curve Tester

Portable EL Tester

Portable Thermal Imaging Tester

Solar Module Multi-Channel Testing System

PV Inverter Power Quality Tester

Drone EL Tester

IV Tester

IVEL Cell Sorting Machine

TOPCon Cell Acetic Acid Fumigation-EL Testing | Rapid Prediction Method for Module Damp-Heat Test Results

Date : 17 November 2025Views : 470

TOPCon solar cell technology is advancing rapidly, yet it faces new reliability challenges stemming from wafer thinning, reduced silver consumption, and the widespread adoption of double-glass structures. While the 1000-hour damp-heat (DH) test per IEC 61215 is critical, its excessive duration fails to meet the demands for rapid process optimization in mass production. This paper proposes an accelerated acetic acid fumigation (AaF) test method at the cell level. By directly controlling acetic acid vapor concentration and temperature, this method bypasses the EVA hydrolysis process. Combined with the visual characterization of metal grid corrosion failure via electroluminescence (EL) testing using the Millennial PL/EL integrated tester, this approach efficiently replicates and quantifies the core failure mechanisms of DH at the cell level.

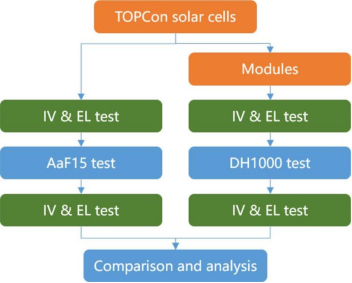

Experimental Design

Experimental Roadmap

DH degradation primarily results from acetic acid corrosion of the battery's metal grid lines (emitter-silver paste interface) caused by hydrolysis of EVA encapsulation, leading to increased contact resistance (evidenced by darkened grid line edges in EL images). This paper proposes an innovative approach: bypassing the EVA hydrolysis process, it directly introduces acetic acid vapor to simulate the corrosion pathway. The method validates consistency between battery-level corrosion and module-level DH failure modes (both exhibit FF and Isc decline).

Cross-verification: Batteries from the same batch were divided into the AaF15 group (50 cells) and the DH1000 module assembly group (300 cells) to compare efficiency decay rates and EL images;

Variable Control: Three experimental groups varied only the silver paste formulation (primary factor), while encapsulation materials (POE/EPE) served as secondary variables to validate universality;

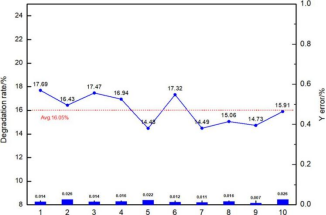

Stability Testing: Corrosion rate error <10% (mean 16.05%) across 10 homogeneous AaF15 cell groups, confirming method reproducibility.

AaF15 Test Results for TOPCon Cells

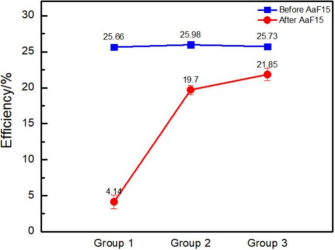

Efficiency Comparison of Three TOPCon Cell Groups Before and After AaF15 Testing

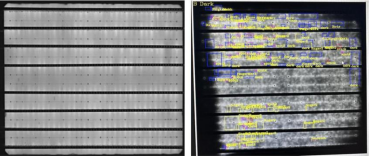

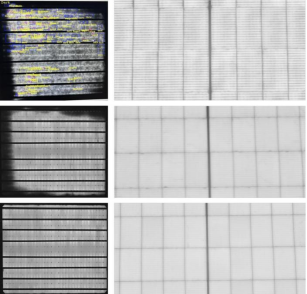

Comparison of Corrosion Features in EL Images of TOPCon Cells

AaF15 testing was conducted on three groups of TOPCon cells using different silver pastes. Significant efficiency degradation (varying in severity) and deterioration in electroluminescence (EL) images (edge darkening, blurred grid lines) were observed in all cases. This indicates that acetic acid successfully induced metal contact corrosion similar to dry etching (DH).

DH1000 Results for TOPCon Modules

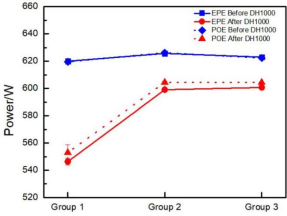

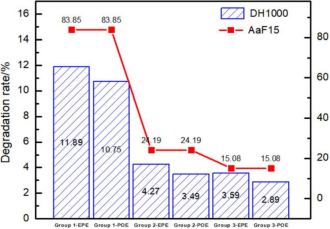

Comparison of DH1000 Degradation Rates Between POE and EPE Encapsulated Modules

Cells from the same batch as the AaF experiments were fabricated into solar modules. These modules underwent DH1000 testing. Each batch of TOPCon cells was divided into two groups, encapsulated using mainstream EPE and POE materials respectively. All DH-tested modules based on either EPE or POE exhibited varying degrees of degradation, consistent with the cell data.

Typical Failure Modes in EL Images of DH1000-Tested Components

EL images of components before and after DH testing reveal increased dark areas near the grid lines and main grid. This pattern aligns with the AaF results for the cells. Additionally, reduced lateral transport capability between the two metal grid lines has caused dark areas to appear in the grid line gaps.

Comparison of Acetic Acid Fumigation Testing with DH1000

Linear mapping relationship between battery AaF15 degradation rate and module DH1000 degradation rate (R²=0.97)

The efficiency degradation rate of batteries after AaF15 shows a significant positive correlation with the power degradation rate of corresponding modules after DH1000. For example:

- Groups with battery degradation >80% exhibited module degradation >10% (far exceeding the 5% control line); For battery groups with ~24% degradation, the module degradation was ~4% (close to the control line); For battery groups with ~15% degradation, the module degradation was <3.6% (better than the control line).

EL Comparison (After AaF15 Battery Treatment vs. After DH1000 Module Treatment vs. Original State)

Compare EL images showing severe degradation, mild degradation, and pre-degradation conditions. The EL degradation observed after AaF15 battery treatment aligns with that after DH1000 module treatment, further validating the predictive methodology.

Stability Verification

Stability Validation of AaF15 Testing for Batch-Matching Batteries

Ten sets of AaF15 tests conducted on batch-matched batteries yielded an average degradation rate of 16.05%, with a fluctuation range of 14.48%–17.69% (maximum error <10%). This demonstrates sufficient stability for mass production monitoring.

The AaF15 accelerated test results for TOPCon cells show significant correlation with module DH1000 outcomes, enabling effective prediction of module DH failure risks. Experimental and error analysis indicate that to ensure module DH1000 degradation ≤5%, cell AaF15 degradation should be controlled below 24%. Practical application recommends adopting a stricter 20% threshold. Requiring only 15 hours, this method provides a rapid, stable, and efficient reliability monitoring tool for TOPCon cell mass production (e.g., silver paste selection, process optimization), significantly reducing mass production risks caused by DH failure.

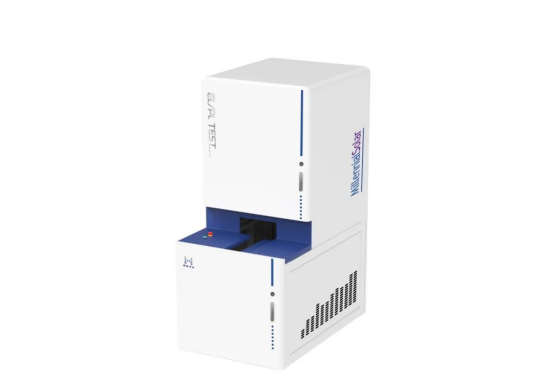

Millennial PL/EL Combo Tester

email:market@millennialsolar.com

The Millennial PL/EL Integrated Tester simulates sunlight irradiation on perovskite solar cells, uniformly illuminating the entire sample. It captures photoluminescence (PL) signals using specialized lenses to generate PL images, and electroluminescence (EL) signals to produce EL images. Image algorithms and software process and analyze the captured PL/EL images, identifying PL/EL defects for subsequent analysis, classification, and summarization based on their characteristics.

EL/PL imaging, 5 megapixels, with multiple imaging precision modes

Spectral response range: 400nm–1200nm

PL light source: Blue light (customizable light source size, wavelength, etc.)

Multiple defect recognition and analysis (pitting, darkening, edge intrusion, etc.) with customizable defect types

The Millennial PL/EL Integrated Tester utilizes electroluminescence (EL) signals to generate EL images, enabling visual characterization of metal grid corrosion failure. It efficiently reproduces and quantifies the core mechanisms of DH failure at the cell level, providing a reliable monitoring tool for TOPCon cell mass production.

Related Products