Quantum Efficiency Tester

PL/EL Integrated System

PV-Reflectumeter

3D Confocal Microscope

In-Line Four Point Probe Tester

Four Point Probe Tester

In-Line Thin Film Thickness Tester

Raman Spectrometer

FTIR Spectrometer

Spectrophotometer

Automatic Spectroscopic Ellipsometer

Contact Resistance Tester

Ultra depth of field 3D microscope

Auto Visual Tester

VMM PV Vision Measuring Machine

Solar Cell Horizontal Tensile Tester

Steady State Solar Simulator for Solar Cell

Solar Cell UV Aging Test Chamber

Solar Cell Comprehensive Tensile Tester

Visual Inspection Tester

Wet Leakage Current Tester

PV Module EL Tester

PV Module UV Preconditioning Chamber

Steady State Solar Simulator for PV Module

Current Continuous Monitor

Potential Induced Degradation Test

Bypass Diode Tester

LeTID Test System

Reverse Current Overload Tester

Impulse Voltage Tester

Hipot Insulation Tester

Ground Continuity Tester

Hipot Insulation Ground Tester

Damp Heat Test Chamber

Humidity Freeze Test

Thermal Cycle Test Chamber

Dynamic Mechanical Load Tester

Static Mechanical Load Tester

Hail Impact Tester

Robustness of Termination Tester

Module Breakage Tester

Cut Susceptibility Tester

Peel Shear Strength Tester

Universal Testing Machine (Single-arm)

Universal Testing Machine (Double-arm)

Glass Transmittance Tester

Acetic Acid Test Chamber

EVA Degree of Crosslinking Test System

Junction Box Comprehensive Tester

Drop ball tester

Semi-automatic scanning four-probe tester

Stylus Profilometer

Maximum Power Point Tracker

Perovskite Glass Transmittance Tester

Perovskite P1 Laser Scribing Multifunctional Testing Machine

Perovskite Online PL Tester

Perovskite Online Sheet Resistance Tester

Online Perovskite Film Thickness Tester

Perovskite Process Inspection Workstation

Portable IV Curve Tester

Portable EL Tester

Portable Thermal Imaging Tester

Solar Module Multi-Channel Testing System

PV Inverter Power Quality Tester

Drone EL Tester

IV Tester

IVEL Cell Sorting Machine

Hot Spot Effect in Solar Panels

Date : 19 November 2025Views : 600

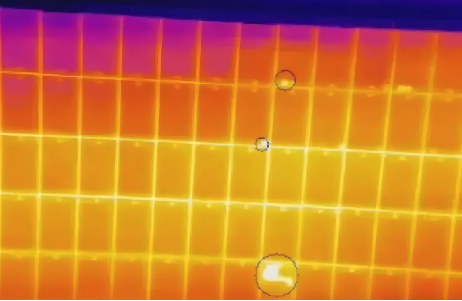

The hot spot effect in Solar Panels occurs when one or more cells (individual solar cells) within a module generate significantly less current than other normal cells under sunlight due to various reasons (such as shading, damage, aging, internal defects, or mismatch). These abnormal cells transform from power-generating units into energy-consuming units, resulting in localized high-temperature spots.

I. Mechanism of Hot Spot Formation

The Mechanism of Hot Spot Formation

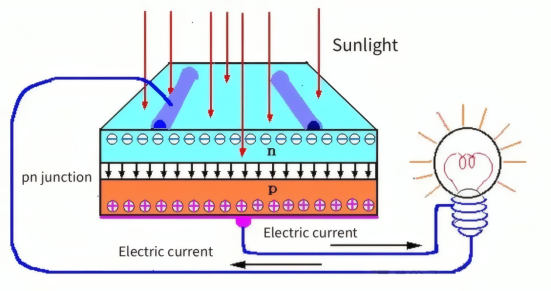

Solar Panels generate electricity because sunlight strikes the p-n junctions within the cells. This interaction creates new electron-hole pairs. Under the influence of the p-n junction electric field, holes flow from the n-region to the p-region, while electrons flow from the p-region to the n-region. When the circuit is closed, a current is formed—this is the photovoltaic effect of the module/cell.

During this power generation process, if an abnormal cell fails to absorb light energy normally, it blocks the occurrence of the photoelectric effect within that cell. The PN junction of the abnormal cell remains electrically neutral and in a blocked state. Meanwhile, the adjacent cell group undergoes the photoelectric effect normally, resulting in a higher voltage at the P-side of the silicon semiconductor compared to the N-side. This creates a potential difference across the abnormal cell, generating voltage. The internal resistance and dark current of the faulty cell also undergo significant changes, transforming it into a power-consuming component. This generates a forward conduction current from the P-side to the N-side. As current flows through this power-consuming component (the faulty cell), heat is generated, leading to the hot spot effect.

II. Causes of Hot Spot Formation

Hot spots caused by cell defects

1. Shading: Shading-induced hot spots are the most common issue in Solar Panel applications. Bird droppings, leaves, dust, shadows from nearby structures or objects, and surface contaminants on the module can all lead to hot spot formation. Shaded cells absorb less light energy, resulting in lower current output compared to other cells, which readily triggers the hot spot effect.

2. Cell Defects: Internal defects within the module's cells (such as cracks, microcracks, fragments, sintering defects, or edge leakage) or abnormally low parallel resistance or high series resistance within the cells.

3. Cell mismatch: Different cells within a module may exhibit varying electrical performance parameters (especially current) due to mixed batches or differing aging rates. This mismatch can easily cause hot spots.

4. Internal module connection failure: Poor soldering or breaks in the busbars, or poor contact in the interconnect strips, can cause abnormal operation in some cells or cell strings.

III. Impacts and Hazards

1. Power Loss: Cells within hot spots cease generating electricity or even consume power, directly reducing the overall output of the module. This decrease in power generation impacts the profitability of photovoltaic power plants.

2. Permanent Module Damage: Local temperatures can exceed 100°C, far surpassing normal operating conditions. Such heat may cause backsheet blistering, carbonization, or cracking, compromising insulation and sealing integrity. Extreme temperatures can directly burn through metal electrodes (bonder wires, busbars) on cells or even shatter the cells themselves. Localized high temperatures generate significant thermal stress, potentially causing glass breakage.

3. Safety Hazards: Persistent hot spots pose a potential fire hazard, especially when the backsheet or encapsulation film ignites. This represents the most severe risk of hot spots. Flexible modules, lacking glass front and back panels, require even more immediate attention when hot spots occur!

5. Reduced Module Lifespan: Even if immediate severe damage is avoided, repeated or prolonged hot spots significantly accelerate material aging and performance degradation, shortening the module's operational lifespan.

IV. Measures to Prevent Hot Spots

1. Module Quality: Select reputable brands with mature manufacturing processes, stringent quality control, and well-designed bypass diodes to prevent hot spots caused by internal cell defects, cell mismatches, or substandard bypass diodes. Bypass diodes enable current generated by other cells to flow through them, ensuring the solar power system continues generating electricity. This prevents circuit interruption due to a single faulty cell. Cell series-parallel circuits and bypass diodes in Solar Panels

2. Proper Installation: Position Solar Panels appropriately, avoiding nearby trees, utility poles, columns, or other structures that could cause localized shading.

3. Maintenance: Regularly clean and maintain Solar Panels, promptly removing obstructions like dust, bird droppings, leaves, and debris accumulated along frame edges from the module surface.

Related Products