Quantum Efficiency Tester

PL/EL Integrated System

PV-Reflectumeter

3D Confocal Microscope

In-Line Four Point Probe Tester

Four Point Probe Tester

In-Line Thin Film Thickness Tester

Raman Spectrometer

FTIR Spectrometer

Spectrophotometer

Automatic Spectroscopic Ellipsometer

Contact Resistance Tester

Ultra depth of field 3D microscope

Auto Visual Tester

VMM PV Vision Measuring Machine

Solar Cell Horizontal Tensile Tester

Steady State Solar Simulator for Solar Cell

Solar Cell UV Aging Test Chamber

Solar Cell Comprehensive Tensile Tester

Visual Inspection Tester

Wet Leakage Current Tester

PV Module EL Tester

PV Module UV Preconditioning Chamber

Steady State Solar Simulator for PV Module

Current Continuous Monitor

Potential Induced Degradation Test

Bypass Diode Tester

LeTID Test System

Reverse Current Overload Tester

Impulse Voltage Tester

Hipot Insulation Tester

Ground Continuity Tester

Hipot Insulation Ground Tester

Damp Heat Test Chamber

Humidity Freeze Test

Thermal Cycle Test Chamber

Dynamic Mechanical Load Tester

Static Mechanical Load Tester

Hail Impact Tester

Robustness of Termination Tester

Module Breakage Tester

Cut Susceptibility Tester

Peel Shear Strength Tester

Universal Testing Machine (Single-arm)

Universal Testing Machine (Double-arm)

Glass Transmittance Tester

Acetic Acid Test Chamber

EVA Degree of Crosslinking Test System

Junction Box Comprehensive Tester

Drop ball tester

Semi-automatic scanning four-probe tester

Stylus Profilometer

Maximum Power Point Tracker

Perovskite Glass Transmittance Tester

Perovskite P1 Laser Scribing Multifunctional Testing Machine

Perovskite Online PL Tester

Perovskite Online Sheet Resistance Tester

Online Perovskite Film Thickness Tester

Perovskite Process Inspection Workstation

Portable IV Curve Tester

Portable EL Tester

Portable Thermal Imaging Tester

Solar Module Multi-Channel Testing System

PV Inverter Power Quality Tester

Drone EL Tester

IV Tester

IVEL Cell Sorting Machine

Solar Panel TC Cycling Test

Date : 25 November 2025Views : 745

I. What is the Solar Panel TC Cycling Test?

Solar Panel Thermal Cycling Test, fully known as Thermal Cycling Test, is one of the most fundamental and critical environmental adaptation tests in Solar Panel reliability testing. Its core purpose is to evaluate a Solar Panel's ability to resist fatigue failure, aging, and electrical performance degradation caused by thermal expansion and contraction under repeatedly changing temperature conditions. Simply put, it simulates whether the module can still function normally after enduring countless temperature cycles during the alternating day and night cycles and seasonal changes experienced outdoors.

II. Test Purpose and Significance

1. Identifying Material Compatibility: Modules are assembled through various processes using multiple materials including glass, EVA/POE encapsulant, solar cells, interconnect ribbons, backsheets, and frames. These materials possess differing thermal expansion coefficients. TC testing effectively reveals incompatibilities between them, such as module delamination or microcracks in solar cells during testing.

2. Evaluating Connection Reliability: Assesses the bonding strength between interconnect strips (bonder wires) and cell busbars, as well as the connection points between busbars and bonder wires. These junctions may fatigue under thermal cycling stress, potentially causing cold solder joints, debonding, or fractures.

3. Predicting Long-Term Lifespan: By performing a large number of temperature cycles (typically 200) in a short period, it simulates 20 years or more of outdoor service life to evaluate the module's long-term durability.

4.Quality Control: TC testing is a critical step for module manufacturers and third-party testing agencies to validate the stability of product design and production processes.

III. Test Principle and Procedure

Testing is conducted in a dedicated environmental test chamber.

1. Sample Preparation: Select intact Solar Panels for testing. Prior to testing, perform initial electrical performance tests (maximum power Pmax, insulation resistance, etc.) and visual inspections (EL inspection is particularly crucial for detecting initial microcracks).

2. Chamber Placement: Position the module inside the temperature-controlled chamber and connect its terminals to external monitoring equipment to track real-time electrical performance changes (e.g., open-circuit voltage, short-circuit current) throughout testing.

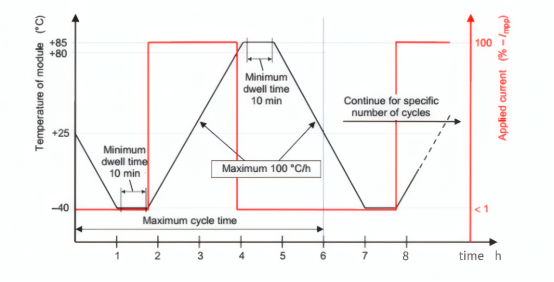

3. Temperature Profile Setup: Testing follows a strictly defined thermal cycling curve, typically comprising the following stages:

High-Temperature Phase: Raise the chamber temperature to 85°C and maintain it for a period (e.g., 10-15 minutes) to ensure overall thermal stabilization of the module.

Cooling Phase: Reduce the temperature to -40°C at a specified rate (typically not exceeding 100°C/hour).

Low-Temperature Phase: Maintain at -40°C for a period to ensure complete cooling of the module.

Rewarm Phase: The temperature is gradually raised back to 85°C at a specified rate.

This completes one full “cycle.”

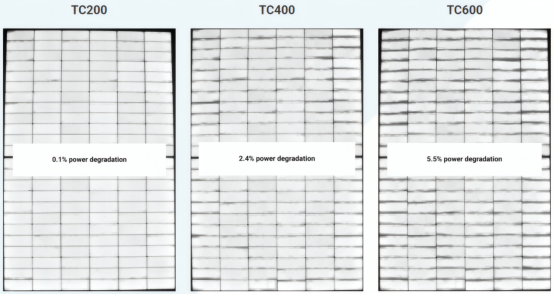

5.Cycle Count: According to standards, TC200 represents the baseline requirement, involving 200 cycles. More stringent testing may mandate TC400 or TC600 to evaluate higher reliability levels.

IV. Post-Test Requirements

After TC testing, modules exhibiting the following issues shall be deemed non-compliant:

1. Severe electrical performance degradation: Maximum power output (Pmax) degradation exceeds the specified standard limit (typically 5%).

2. Insulation failure: Insulation resistance fails to meet requirements, posing leakage risks.

3. Visual defects:

Cell cracking/microcracks: The most common failure mode. Post-test EL (electroluminescence) imaging clearly reveals hidden crack patterns.

Tape breakage/de-soldering: Causes partial or complete circuit disconnection in cell strings, resulting in significant power reduction.

Bubbles or delamination: Stress-induced separation between material layers, impairing heat dissipation and insulation.

Junction box seal failure: Allows moisture ingress.

Back sheet or glass cracking.

Related Products