Quantum Efficiency Tester

PL/EL Integrated System

PV-Reflectumeter

3D Confocal Microscope

In-Line Four Point Probe Tester

Four Point Probe Tester

In-Line Thin Film Thickness Tester

Raman Spectrometer

FTIR Spectrometer

Spectrophotometer

Automatic Spectroscopic Ellipsometer

Contact Resistance Tester

Ultra depth of field 3D microscope

Auto Visual Tester

VMM PV Vision Measuring Machine

Solar Cell Horizontal Tensile Tester

Steady State Solar Simulator for Solar Cell

Solar Cell UV Aging Test Chamber

Solar Cell Comprehensive Tensile Tester

Visual Inspection Tester

Wet Leakage Current Tester

PV Module EL Tester

PV Module UV Preconditioning Chamber

Steady State Solar Simulator for PV Module

Current Continuous Monitor

Potential Induced Degradation Test

Bypass Diode Tester

LeTID Test System

Reverse Current Overload Tester

Impulse Voltage Tester

Hipot Insulation Tester

Ground Continuity Tester

Hipot Insulation Ground Tester

Damp Heat Test Chamber

Humidity Freeze Test

Thermal Cycle Test Chamber

Dynamic Mechanical Load Tester

Static Mechanical Load Tester

Hail Impact Tester

Robustness of Termination Tester

Module Breakage Tester

Cut Susceptibility Tester

Peel Shear Strength Tester

Universal Testing Machine (Single-arm)

Universal Testing Machine (Double-arm)

Glass Transmittance Tester

Acetic Acid Test Chamber

EVA Degree of Crosslinking Test System

Junction Box Comprehensive Tester

Drop ball tester

Semi-automatic scanning four-probe tester

Stylus Profilometer

Maximum Power Point Tracker

Perovskite Glass Transmittance Tester

Perovskite P1 Laser Scribing Multifunctional Testing Machine

Perovskite Online PL Tester

Perovskite Online Sheet Resistance Tester

Online Perovskite Film Thickness Tester

Perovskite Process Inspection Workstation

Portable IV Curve Tester

Portable EL Tester

Portable Thermal Imaging Tester

Solar Module Multi-Channel Testing System

PV Inverter Power Quality Tester

Drone EL Tester

IV Tester

IVEL Cell Sorting Machine

Back-contact IBC solar cells achieve 25.2% efficiency through enhanced passivation and anti-reflective coating technologies

Date : 28 November 2025Views : 405

IBC solar cells leverage their back-contact design (where all electrodes are positioned on the rear surface) to eliminate light-blocking losses caused by front-side metal busbars, thereby enhancing light absorption efficiency. However, their manufacturing process is complex and costly, with the primary technical challenge lying in achieving effective surface passivation and fine-tuning related parameters. This study systematically analyzed the influence of key parameters—including crystalline silicon (c-Si) bulk lifetime, wafer resistivity, back-side boron-doped layer sheet resistance, and recombination current density (J₀)—on cell performance using Quokka3 simulation software. The Millennial four-probe resistance tester enables rapid, automated scanning of cell samples to obtain sheet resistance/resistivity distribution data across different locations.

Research Methodology

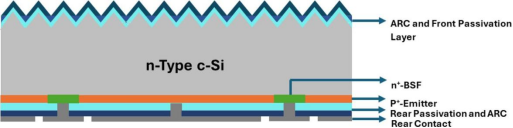

This study simulates the IBC cell structure using Quokka3 software. The simulated cell employs an n-type crystalline silicon (c-Si) wafer as the substrate. The cell front is coated with a passivation layer and anti-reflective coating (ARC) to optimize photon capture and minimize losses. The rear surface features a p⁺-type emitter and an n⁺-type backsurface field (BSF), arranged in an interleaved pattern without physical isolation zones to enhance electrical continuity. Optimized rear passivation/anti-reflective coating and electrode design further reduce recombination losses.

Schematic Diagram of IBC Solar Cell Structure

Key simulation parameters include:

Cell thickness: 150 μm

Wafer resistivity: 0.6–1.8 Ω·cm

Volume lifetime (SRH electron/hole lifetime): 1–5 ms

Emitter sheet resistance: 100–500 Ω/sq

BSF sheet resistance: 35 Ω/sq

Front surface passivation recombination current density J₀: 1–60 fA/cm²

Back surface passivation recombination current density J₀: 1–60 fA/cm²

Emitter/BSF contact resistance: 2×10⁻⁵ Ω·cm²

Effect of c-Si Bulk Lifetime and Wafer Resistivity

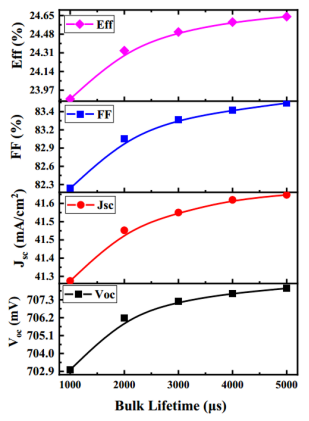

Simulation results of electrical parameters in IBC solar cells as a function of n-type c-Si wafer bulk lifetime

Extending the c-Si bulk lifetime (1–5 ms) significantly enhances Voc, Jsc, FF, and η. Increased bulk lifetime directly reduces carrier recombination rate, thereby decreasing the saturation current density I₀ and leading to higher Voc. Simultaneously, increased carrier diffusion length enhances the collection efficiency of photo-generated carriers, thereby improving Jsc and FF. Simulation results indicate that when the body lifetime reaches 5 ms, the cell efficiency η can reach a maximum of 24.64%, fully demonstrating the critical role of high-quality silicon material in cell performance and reliability.

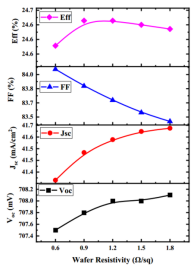

Simulation Results of IBC Solar Cell Electrical Parameters as a Function of n-Type c-Si Wafer Resistivity

The impact of wafer resistivity variation (0.6–1.8 Ω·cm) on cell performance exhibits nonlinear characteristics. Within the 0.6–1.2 Ω·cm range, both Voc and Jsc increase with rising resistivity. This primarily stems from higher resistivity broadening the pn-junction depletion layer width, which reduces bulk recombination losses and enhances absorption of longer-wavelength photons. When resistivity exceeds 1.2 Ω·cm, increased series resistance causes FF to decrease, and efficiency begins to decline after reaching its peak. Simulation results indicate that cell efficiency peaks at 24.65% when resistivity is 1.2 Ω·cm, demonstrating that optimizing wafer resistivity is crucial for balancing material conductivity and recombination losses.

Impact of Back-Side Boron-Doped Layer Sheet Resistance

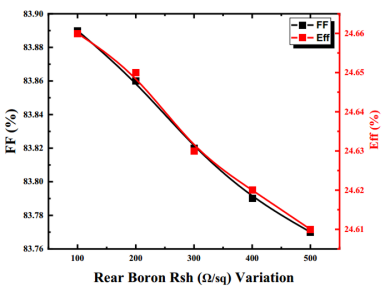

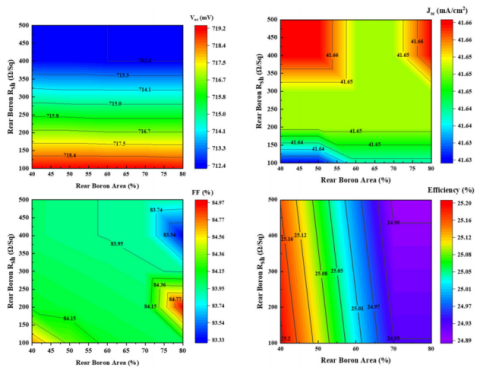

Quokka3 Simulation Results on the Effect of Back Boron Doped Layer Sheet Resistance (Rsh) on FF and η of IBC Solar Cells

Simulation results indicate that an increase in the square resistance Rₛₕ of the rear boron-doped layer leads to a slight decrease in FF and a reduction in conversion efficiency η. This is primarily due to the elevated Rₛₕ increasing the cell's series resistance, hindering efficient carrier collection and transport, and resulting in a deterioration of the I-V curve's “squareness.” Notably, the open-circuit voltage Voc and short-circuit current density Jsc remain largely unaffected by Rₛₕ variations, as they are determined by the material's bandgap and light absorption capacity, respectively. This highlights the significant influence of the back-emitter characteristics on FF, underscoring the critical importance of optimizing boron doping concentration to balance conductivity and recombination.

Effect of recombination current density J₀ on passivation efficiency

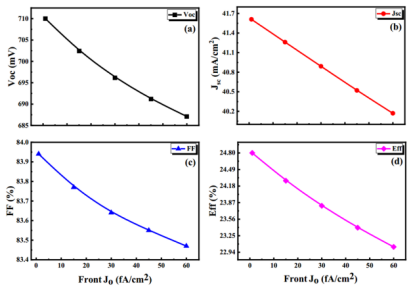

Effect of Front Surface Recombination Layer Composite Current Density (J₀) on Electrical Parameters of Quokka3-Simulated IBC Cells

An increase in front-surface recombination current density J₀ leads to a comprehensive decrease in Voc, Jsc, FF, and η. Higher J₀ values indicate intensified front-surface recombination, reducing the number of photogenerated carriers available for collection and degrading the I-V curve characteristics. Simulation data indicates that efficiency begins to decline significantly when J₀ exceeds approximately 30 fA/cm², underscoring the necessity of applying a high-quality passivation layer on the front surface.

Effect of Back Surface Passivation Layer Recombination Current Density (J₀) on Electrical Parameters of Quokka3-Simulated IBC Cells

Increasing the back recombination current density J₀ similarly reduces Voc, Jsc, FF, and η. For IBC cells, where all charge collection occurs via the back contact, the impact of J₀ on passivation quality is particularly critical. An elevated J₀ directly increases recombination losses in the pn junction bend region, significantly degrading Voc and FF. Selective passivation techniques (e.g., Al₂O₃ on the p⁺ emitter and SiO₂ on the n⁺ BSF) can effectively reduce recombination and enhance Voc. However, the design and passivation of the pn junction region remain sensitive factors affecting the pseudo-fill factor (pFF).

Interaction Between Emitter Coverage and Back Boron Sheet Resistance

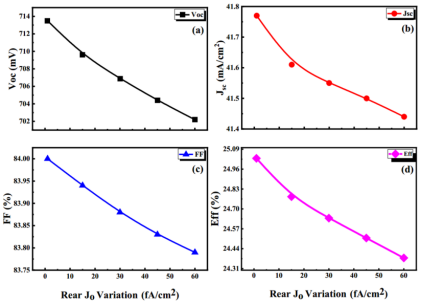

Simulation of the Combined Effect of Back Boron Sheet Resistance and Coverage on IBC Cell Parameters

The synergistic optimization of emitter coverage and back boron sheet resistance is central to achieving peak efficiency. Simulation results indicate that optimal cell performance is achieved at an emitter coverage of approximately 40% and a rear boron block resistance Rₛₕ = 100 Ω/sq: Voc = 719.2 mV, Jsc = 41.66 mA/cm², FF = 84.71%, conversion efficiency η = 25.2%. This optimized point effectively balances recombination losses in the contact area and resistive losses. When coverage falls below 40%, current aggregation effects cause significant loss increases; when coverage exceeds 40%, recombination losses from the large passivated surface area begin to dominate, offsetting the benefits of low contact resistance.

This paper systematically investigates the optimization of passivation and antireflection techniques for IBC solar cells. Through Quokka3 simulations, it reveals the efficiency enhancement mechanisms achieved by fine-tuning c-Si bulk lifetime, sheet resistance, and J₀. For the first time, it integrates the interactive effects of bulk lifetime, resistivity, backside boron sheet resistance, and emitter coverage, achieving a peak efficiency of 25.2% and establishing a new industry benchmark.

Millennial Four-Probe Resistivity Tester

email:market@millennialsolar.com

The Millennial Four-Probe Resistance Tester enables rapid, automated scanning of samples up to 230mm in size, capturing sheet resistance/resistivity distribution data across different positions. It finds extensive applications in photovoltaics, semiconductors, alloys, ceramics, and numerous other fields.

Ultra-wide measurement range: 1mΩ to 100MΩ

High-precision measurement with dynamic repeatability up to 0.2%

Fully automated multi-point scanning with multiple preset schemes and customizable adjustments

Rapid material characterization with automatic calibration factor calculation

The Millennial Four-Probe Resistance Tester serves as the core experimental equipment for obtaining key electrical parameters of IBC cells. Its role spans the entire process from material screening and process monitoring to performance verification, supporting experimental reproducibility at the 25.2% efficiency optimization point. Its data directly determines the reliability of research conclusions and industrial implementation value.

Related Products