Quantum Efficiency Tester

PL/EL Integrated System

PV-Reflectumeter

3D Confocal Microscope

In-Line Four Point Probe Tester

Four Point Probe Tester

In-Line Thin Film Thickness Tester

Raman Spectrometer

FTIR Spectrometer

Spectrophotometer

Automatic Spectroscopic Ellipsometer

Contact Resistance Tester

Ultra depth of field 3D microscope

Auto Visual Tester

VMM PV Vision Measuring Machine

Solar Cell Horizontal Tensile Tester

Steady State Solar Simulator for Solar Cell

Solar Cell UV Aging Test Chamber

Solar Cell Comprehensive Tensile Tester

Visual Inspection Tester

Wet Leakage Current Tester

PV Module EL Tester

PV Module UV Preconditioning Chamber

Steady State Solar Simulator for PV Module

Current Continuous Monitor

Potential Induced Degradation Test

Bypass Diode Tester

LeTID Test System

Reverse Current Overload Tester

Impulse Voltage Tester

Hipot Insulation Tester

Ground Continuity Tester

Hipot Insulation Ground Tester

Damp Heat Test Chamber

Humidity Freeze Test

Thermal Cycle Test Chamber

Dynamic Mechanical Load Tester

Static Mechanical Load Tester

Hail Impact Tester

Robustness of Termination Tester

Module Breakage Tester

Cut Susceptibility Tester

Peel Shear Strength Tester

Universal Testing Machine (Single-arm)

Universal Testing Machine (Double-arm)

Glass Transmittance Tester

Acetic Acid Test Chamber

EVA Degree of Crosslinking Test System

Junction Box Comprehensive Tester

Drop ball tester

Semi-automatic scanning four-probe tester

Stylus Profilometer

Maximum Power Point Tracker

Perovskite Glass Transmittance Tester

Perovskite P1 Laser Scribing Multifunctional Testing Machine

Perovskite Online PL Tester

Perovskite Online Sheet Resistance Tester

Online Perovskite Film Thickness Tester

Perovskite Process Inspection Workstation

Portable IV Curve Tester

Portable EL Tester

Portable Thermal Imaging Tester

Solar Module Multi-Channel Testing System

PV Inverter Power Quality Tester

Drone EL Tester

IV Tester

IVEL Cell Sorting Machine

Solar Panel Production Process—Lamination

Date : 4 December 2025Views : 415

The lamination process for Solar Panels is the core step determining their performance and lifespan! Using high-temperature and high-pressure technology, it “fuses” materials such as solar cells, glass, and EVA adhesive film into a robust integrated unit. This not only enhances power generation efficiency but also ensures the module's stability under extreme environmental conditions.

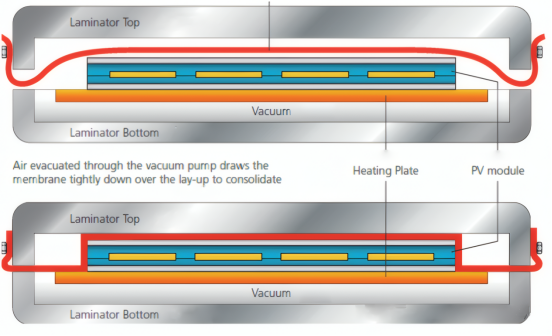

Laminator Working Principle:

The main structure of a laminator consists of the following components

Base Plate: Also known as the heating plate, its surface is flat without protrusions or depressions. Typically, it contains high-temperature oil or electric heating rods to heat the base plate to the desired temperature.

Upper Cover: Equipped with a silicone plate, sealing rings, and other components. It can be pressurized via an inflation pipe to inflate the silicone plate, applying pressure to the assembly.

Upper Chamber: The space between the silicone sheet and the upper cover.

Lower Chamber: The space between the base plate and the upper cover.

Vacuum Pump: Used to evacuate air from either the lower or upper chamber.

Air Pump: Used to inflate either the lower or upper chamber.

With this understanding, we can now examine how the laminator operates. When the module enters the laminator, the following sequence begins:

Step 1: Lid Closure

The upper lid descends under hydraulic cylinder pressure until it reaches the qualified position. At this point, the sealing ring on the upper lid makes tight contact with the base, forming a sealed chamber known as the lower chamber.

Step 2: Vacuum Extraction: The vacuum pump starts and begins the vacuuming process, which typically lasts about 6 minutes. During vacuuming, since the base plate is heated, the module is continuously heated after entering the laminator until it reaches the same temperature as the base. During this heating process, the adhesive film melts, transitioning from a solid to a liquid state. The vacuum environment allows gases trapped within the liquid adhesive film to escape from the module. This ensures the laminated module remains bubble-free.

Step 3: Gas-Pressure Laminating: The upper chamber is pressurized with air. The flexible silicone sheet deforms and expands, tightly conforming to the module under air pressure. This applies significant pressure to the module, forcing any remaining internal air bubbles to escape further. Simultaneously, the high temperature and pressure cause the flowing adhesive film to transition from liquid to solid state, initiating the cross-linking process. After inflation, the silicone sheet adheres tightly to the module, preventing the flowing adhesive film inside the module from completely escaping under pressure.

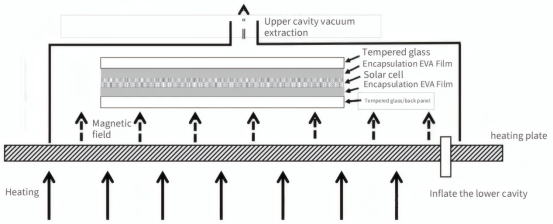

Schematic Diagram of Upper Inflatable Laminate

Step 4: Pressure Maintenance: After the upper chamber is pressurized to a specific level, it maintains constant pressure for a set duration. During this period, the adhesive film gradually crosslinks until the desired degree of crosslinking is achieved. At this point, the lower chamber can be pressurized to release the vacuum state, while the upper chamber is evacuated to relieve pressure. The upper cover separates from the base plate, and the component can be transferred to the cooling chamber for cooling before being discharged.

Pressure Holding Diagram

Note:

① The module does not come into direct contact with the silicone sheet or base plate; instead, a layer of non-stick cloth is interposed (to prevent the melted adhesive film from adhering to the base plate and silicone sheet).

② Modern Solar Panel laminators typically operate in three distinct chambers across three sequential stages:

Stage 1: Apply a low temperature to the substrate to melt the adhesive film. Evacuate the chamber and apply a low pressure to facilitate film melting and remove internal bubbles from the module.

Stage 2: Increase the substrate temperature significantly. Maintain vacuum conditions while applying high pressure to induce film cross-linking.

Stage 3: Vacuum is applied with very low pressure, while the substrate maintains a temperature around 20°C to cool the module.

This three-stage process is implemented to enhance the laminator's operational efficiency.

The primary purpose of the first stage is to melt the encapsulant and expel air bubbles. Therefore, the temperature should not be excessively high, and the pressure should not be too great. Otherwise, the encapsulant will cross-link prematurely, preventing internal bubbles from being properly expelled, resulting in bubbles within the module. (Typically around 120°C)

The second stage primarily aims to cross-link the encapsulant film. Therefore, higher temperatures and greater pressure are applied to accelerate the cross-linking process (around 140°C).

The third stage, cooling, is solely for cooling the module. Only minimal pressure is applied to prevent deformation or warping during the cooling process.

Some Abnormalities in Module Laminating Process

① Bubbles on cell surface: May result from excessive temperature during a specific stage, where bubbles were not fully evacuated before the film began cross-linking, trapping bubbles inside the module; abnormal vacuum extraction, insufficient vacuum rate preventing proper bubble removal; or insufficient vacuum extraction time.

② Snowflake-like bubbles at edges or corners: Caused by improper laminating frame height or size.

③ Insufficient tensile strength or crosslinking degree: Caused by low temperature, insufficient pressure, inadequate pressure holding time, or substandard laminating film quality.

④ Cell fragmentation after lamination: Resulting from excessive lamination pressure, foreign objects on the high-temperature cloth, or surface irregularities.

⑤ Bubbles around solder ribbons: Attributed to poor flux quality or insufficient flux drying.