Quantum Efficiency Tester

PL/EL Integrated System

PV-Reflectumeter

3D Confocal Microscope

In-Line Four Point Probe Tester

Four Point Probe Tester

In-Line Thin Film Thickness Tester

Raman Spectrometer

FTIR Spectrometer

Spectrophotometer

Automatic Spectroscopic Ellipsometer

Contact Resistance Tester

Ultra depth of field 3D microscope

Auto Visual Tester

VMM PV Vision Measuring Machine

Solar Cell Horizontal Tensile Tester

Steady State Solar Simulator for Solar Cell

Solar Cell UV Aging Test Chamber

Solar Cell Comprehensive Tensile Tester

Visual Inspection Tester

Wet Leakage Current Tester

PV Module EL Tester

PV Module UV Preconditioning Chamber

Steady State Solar Simulator for PV Module

Current Continuous Monitor

Potential Induced Degradation Test

Bypass Diode Tester

LeTID Test System

Reverse Current Overload Tester

Impulse Voltage Tester

Hipot Insulation Tester

Ground Continuity Tester

Hipot Insulation Ground Tester

Damp Heat Test Chamber

Humidity Freeze Test

Thermal Cycle Test Chamber

Dynamic Mechanical Load Tester

Static Mechanical Load Tester

Hail Impact Tester

Robustness of Termination Tester

Module Breakage Tester

Cut Susceptibility Tester

Peel Shear Strength Tester

Universal Testing Machine (Single-arm)

Universal Testing Machine (Double-arm)

Glass Transmittance Tester

Acetic Acid Test Chamber

EVA Degree of Crosslinking Test System

Junction Box Comprehensive Tester

Drop ball tester

Semi-automatic scanning four-probe tester

Stylus Profilometer

Maximum Power Point Tracker

Perovskite Glass Transmittance Tester

Perovskite P1 Laser Scribing Multifunctional Testing Machine

Perovskite Online PL Tester

Perovskite Online Sheet Resistance Tester

Online Perovskite Film Thickness Tester

Perovskite Process Inspection Workstation

Portable IV Curve Tester

Portable EL Tester

Portable Thermal Imaging Tester

Solar Module Multi-Channel Testing System

PV Inverter Power Quality Tester

Drone EL Tester

IV Tester

IVEL Cell Sorting Machine

University of New South Wales Study Reveals Degradation Mechanism of TOPCon Cells: Role of Wavelength Dependence and Hydrogen Redistribution

Date : 16 December 2025Views : 400

Tunnel Oxide Passivated Contact (TOPCon) solar cells dominate the global photovoltaic market due to their high efficiency and low cost. TOPCon solar cells and modules undergo ultraviolet-induced degradation (UVID) under ultraviolet (UV) radiation. This study employed UV-A (315–400 nm) and UV-B (280–315 nm) exposure experiments to investigate the effects of UV radiation on TOPCon precursors and lifetime structures. The Millennial composite UV aging chamber provided critical technical support through its controllable UV light source and temperature/humidity regulation capabilities. Results indicate that UV-B and UV-A exposure cause similar degradation levels, but the degradation process is significantly faster under UV-B, suggesting UV-B can be used to accelerate UV degradation testing.

TOPCon Cell Fabrication and Experimental Design

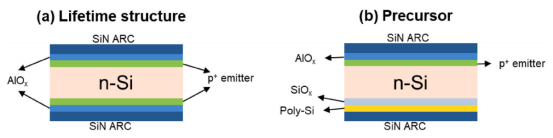

(a) Symmetrical lifetime structure; (b) TOPCon precursor

Sample Preparation: Symmetrical lifetime structures and TOPCon precursors were fabricated using n-type CZ silicon wafers (182 × 182 mm², thickness 140 ± 10 μm) manufactured on an industrial line. The lifetime structures featured boron-diffused emitters on both sides, with a passivation layer of 5 nm Al₂O₃ (atomic layer deposition) over a 75 nm PECVD SiN₂:H antireflection layer. The front side of the TOPCon precursor featured the same structure, while the back side comprised ~1.5 nm tunnel SiOₓ, a 150 nm phosphorus-doped polysilicon layer, and a 75 nm SiNₓ:H layer. Some samples underwent sintering at a peak temperature of 850°C.

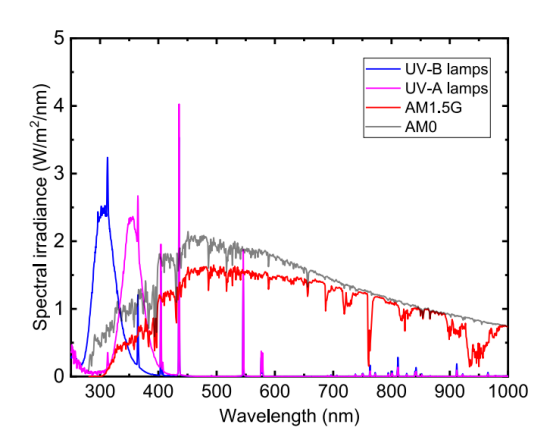

AM0 and AM1.5G standard spectra and UV-A and UV-B light spectrum irradiance

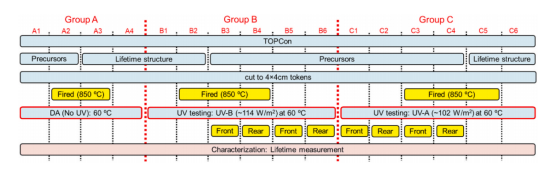

UV Irradiation and Experimental Design: Irradiation was conducted at 60°C using a proprietary UV lamp system. The UV-A lamp delivered an irradiance of 102 W/m² in the 315–420 nm range, while the UV-B lamp provided 114 W/m² in the 250–385 nm range. Total doses were 49 kWh/m² for UV-A and 61.1 kWh/m² for UV-B. Samples were divided into three groups: Group A: 60°C dark annealing (DA), serving as a thermal effect control; Group B: UV-B irradiation; Group C: UV-A irradiation. Each group included sintered and unsintered samples, with testing conducted on both front and back surfaces.

Schematic of the experimental workflow for investigating the effects of ultraviolet radiation on TOPCon precursors and lifetime structures

Characterization and Simulation: Effective minority carrier lifetime and emitter saturation current density (J₀ₑ) were measured via quasi-steady-state photocurrent (QSS-PC) measurements, with normalized defect density (NDD) calculated. Time-of-flight secondary ion mass spectrometry (ToF-SIMS) analyzed elemental depth profiles, complemented by optical simulation software SunSolve to evaluate the back-surface structure's UV absorption characteristics.

Thermal Stability and LeTID Behavior

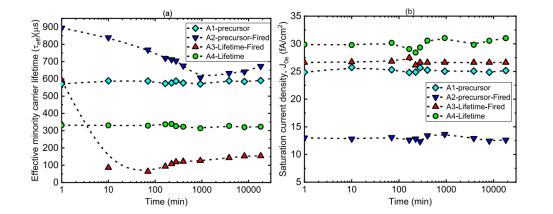

(a) Changes in effective lifetime of all samples in Group A during dark annealing at 60 °C; (b) Saturated current density extracted based on effective lifetime versus dark annealing time

During dark annealing, the effective lifetime of unsintered samples in Group A remained stable, while sintered samples exhibited a trend of initial decay followed by recovery. The constant J₀ₑ indicates stable surface passivation, with bulk defects driving the changes—consistent with light-induced thermal decay (LeTID) characteristics.

UV-B Radiation Experiment

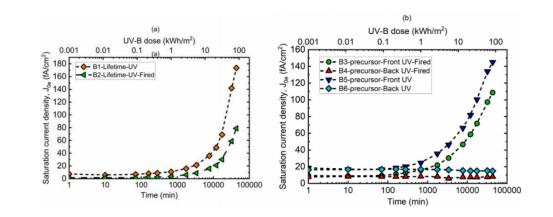

Saturation current density of Group B samples at 60 °C as a function of UV-B exposure time: (a) aged samples, (b) precursor samples (UV irradiation applied to front and back sides respectively)

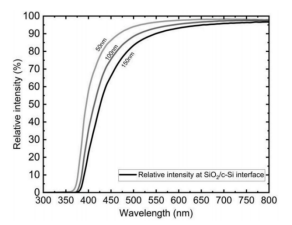

Simulated reflectance (red) on the rear side of the TOPCon structure and simulated absorption rates for polysilicon layers of 50 nm, 100 nm, and 150 nm thickness

Optical simulations indicate strong absorption and reflection of UV light <370 nm by the polysilicon layer. A 150 nm polysilicon layer effectively protects the tunnel oxide layer; reducing thickness to 50 or 100 nm increases UVID risk.

UV-A radiation experiments

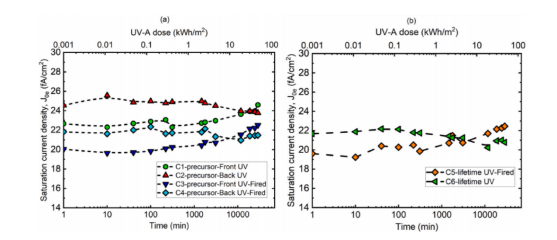

At 60°C, the variation in saturation current density of Group C samples with UV-A exposure time: (a) Precursor: (b) Lifetime structure

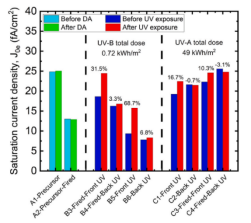

Saturation current density of Groups A, B, and C samples before and after testing

Both UV-B and UV-A exposure caused an increase in front-side J₀ₑ, indicating enhanced surface recombination. UV-B exhibited a faster decay rate but ultimately reached a similar attenuation level to UV-A. Under back-side irradiation, J₀ₑ showed minimal change, demonstrating the ultraviolet shielding effect of the polysilicon layer.

Hydrogen kinetics and bulk defect behavior

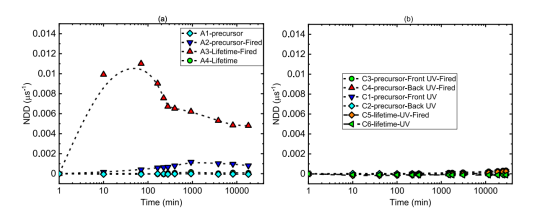

Changes in normalized defect density (NDD) at 60°C: (a) Group A samples over annealing time; (b) Group C samples over UV-A exposure time

NDD analysis reveals that dark-annealed sintered samples exhibit a LeTID-like pattern of initially rising then decreasing NDD, whereas UV-irradiated samples show minimal NDD variation. This indicates that UV radiation suppresses bulk defect formation but intensifies surface recombination.

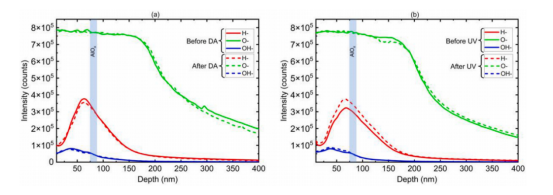

ToF-SIMS depth profiles: Pre-sintered precursors (a) A2 before and after dark annealing; (b) C3 before and after UV-A irradiation

ToF-SIMS revealed increased hydrogen concentration at the AlOₓ/p⁺/Si interface post-UV irradiation, indicating hydrogen redistribution due to Si-H bond cleavage. The absence of LeTID under UV irradiation suggests UV suppression of bulk defect formation.

This paper systematically reveals the degradation behavior and mechanisms of TOPCon solar cells under ultraviolet radiation. Both UV-A and UV-B can cause similar types of surface degradation, but UV-B exhibits a faster degradation rate, making it suitable for accelerated UVID testing of ultraviolet-induced degradation in solar cells. The front surface exhibits significant sensitivity to UVID, whereas the rear surface demonstrates superior degradation resistance due to the high UV absorption of the polycrystalline silicon layer. UV irradiation disrupts Si–H bonds, triggers hydrogen redistribution, and suppresses the occurrence of light-induced thermal degradation (LeTID). These findings provide crucial insights for enhancing the UV resistance and reliability of TOPCon cells.

Millennial Composite UV Aging Test Chamber

The Millennial Composite UV Aging Test Chamber performs accelerated aging tests. This chamber delivers ultraviolet spectra ranging from 280 to 400 nm, simulating the UV component of sunlight while maintaining an irradiance intensity of 150 to 250 W/m² to accelerate the aging process.

email:market@millennialsolar.com

Irradiance: 150-250 W/m² (Customizable 500-1000 W/m² Super UV)

UVB Content: 3%-9%

Spectral Range: 280-400nm

Through controllable UV light sources, temperature and humidity regulation, and other conditions, Millennial composite UV aging test chamber achieves accelerated testing of ultraviolet-induced degradation (UVID) in solar cells. This provides crucial data for reliability optimization of TOPCon cells and design of bifacial modules.

Related Products