Quantum Efficiency Tester

PL/EL Integrated System

PV-Reflectumeter

3D Confocal Microscope

In-Line Four Point Probe Tester

Four Point Probe Tester

In-Line Thin Film Thickness Tester

Raman Spectrometer

FTIR Spectrometer

Spectrophotometer

Automatic Spectroscopic Ellipsometer

Contact Resistance Tester

Ultra depth of field 3D microscope

Auto Visual Tester

VMM PV Vision Measuring Machine

Solar Cell Horizontal Tensile Tester

Steady State Solar Simulator for Solar Cell

Solar Cell UV Aging Test Chamber

Solar Cell Comprehensive Tensile Tester

Visual Inspection Tester

Wet Leakage Current Tester

PV Module EL Tester

PV Module UV Preconditioning Chamber

Steady State Solar Simulator for PV Module

Current Continuous Monitor

Potential Induced Degradation Test

Bypass Diode Tester

LeTID Test System

Reverse Current Overload Tester

Impulse Voltage Tester

Hipot Insulation Tester

Ground Continuity Tester

Hipot Insulation Ground Tester

Damp Heat Test Chamber

Humidity Freeze Test

Thermal Cycle Test Chamber

Dynamic Mechanical Load Tester

Static Mechanical Load Tester

Hail Impact Tester

Robustness of Termination Tester

Module Breakage Tester

Cut Susceptibility Tester

Peel Shear Strength Tester

Universal Testing Machine (Single-arm)

Universal Testing Machine (Double-arm)

Glass Transmittance Tester

Acetic Acid Test Chamber

EVA Degree of Crosslinking Test System

Junction Box Comprehensive Tester

Drop ball tester

Semi-automatic scanning four-probe tester

Stylus Profilometer

Maximum Power Point Tracker

Perovskite Glass Transmittance Tester

Perovskite P1 Laser Scribing Multifunctional Testing Machine

Perovskite Online PL Tester

Perovskite Online Sheet Resistance Tester

Online Perovskite Film Thickness Tester

Perovskite Process Inspection Workstation

Portable IV Curve Tester

Portable EL Tester

Portable Thermal Imaging Tester

Solar Module Multi-Channel Testing System

PV Inverter Power Quality Tester

Drone EL Tester

IV Tester

IVEL Cell Sorting Machine

HJT Cell PVD Process

Date : 19 December 2025Views : 290

Physical Vapor Deposition (PVD) is a critical step in the fabrication process of HJT heterojunction cells. This technology utilizes a vacuum environment to induce physical evaporation or sputtering of material sources, causing gaseous atoms or molecules to deposit onto the substrate surface and form high-quality thin films. In HJT cell manufacturing, the PVD process is primarily used to prepare the transparent conductive oxide (TCO) layer. This layer significantly impacts the cell's electrical conductivity and optical properties. Excellent electrical conductivity helps reduce series resistance and enhance carrier collection efficiency. Meanwhile, ideal optical properties improve light absorption and minimize reflection losses, playing a decisive role in the cell's overall conversion efficiency.

I. Role and Positioning of PVD in HJT Cells

The structure of an HJT cell, from top to bottom, typically consists of: metal grid lines → transparent conductive oxide (TCO) film → amorphous silicon film (intrinsic layer and doped layer) → crystalline silicon substrate → amorphous silicon film → TCO film → metal grid lines.

The core task of the PVD process here is to deposit a high-quality transparent conductive oxide (TCO) film onto the amorphous silicon films at both ends.

This TCO film serves three critical functions:

1. Lateral Conductivity: Collects photo-generated carriers from the amorphous silicon layers and conducts them to the metal grid lines. Amorphous silicon itself has extremely low lateral conductivity and cannot efficiently collect charge, making the TCO layer an indispensable “conductive highway.”

2. Anti-reflection and transmittance enhancement: Acts as an anti-reflective layer, reducing reflection losses of incident light and increasing the cell's absorption of sunlight.

3. Protective layer: Shields the fragile intrinsic and amorphous silicon layers from damage during subsequent screen printing processes.

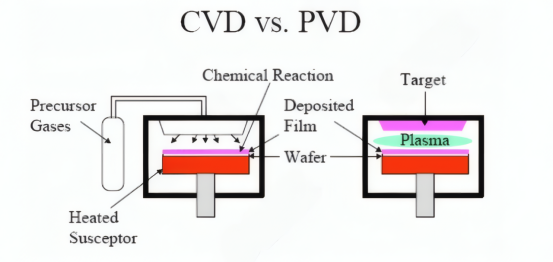

II. Fundamental Principles of PVD Processes

Physical Vapor Deposition (PVD)

PVD is a process that vaporizes solid target materials (raw materials) through physical methods, transports them in a vacuum environment, and ultimately condenses them into solid-state films on substrate surfaces.

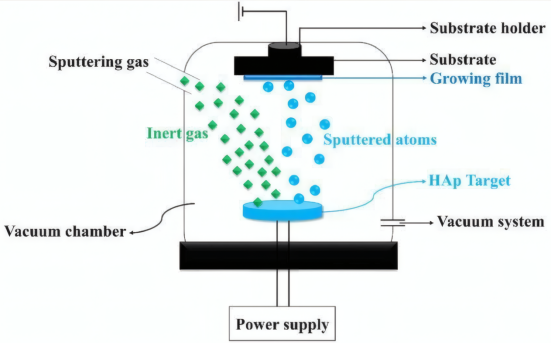

In TCO deposition for HJT cells, magnetron sputtering is the most prevalent PVD technique. Its operating principle can be broken down into the following steps:

1. Establishing the Vacuum Environment: Silicon wafers are loaded into the vacuum chamber and evacuated to a high vacuum level (e.g., 10⁻³ Pa). This eliminates interference from air molecules, prevents target oxidation and film contamination, and ensures film purity and quality.

2. Process gas introduction: High-purity process gas, typically argon, is introduced into the chamber with precisely controlled flow rates. Argon, being an inert gas, does not chemically react with the target material during subsequent discharge processes, hence the term “reactive sputtering.”

3. Plasma generation: A high voltage (usually DC or RF power). Free electrons are accelerated by the electric field. Upon gaining sufficient energy, they collide with argon atoms, ionizing them into argon ions and additional electrons. This avalanche-like process forms a glow plasma within the chamber, composed of numerous electrons and ions.

4. Sputtering Process: Positively charged argon ions are accelerated by the electric field and bombard the surface of the target material connected to the cathode at high speed. This high-energy impact acts like a “billiard ball collision,” transferring momentum to “sputter” atoms or molecules from the target material. These particles are ejected from the target surface and disperse into the surrounding space in gaseous form.

5. Thin Film Deposition: Atomized atoms/molecules from the target material travel through the vacuum chamber, ultimately reaching and depositing onto the silicon wafer surface. These particles migrate, nucleate, and grow on the wafer surface, eventually forming a dense, uniform TCO film.

6.Magnetic Field Enhancement: Specially designed permanent magnets or electromagnets are placed behind the target material to generate a magnetic field. The magnetic field confines electrons, causing them to spiral near the target surface. This significantly increases the collision paths and probability between electrons and argon atoms. Consequently, a high-density plasma can be maintained at lower gas pressures and voltages, substantially boosting sputtering rates while reducing bombardment damage to the silicon wafer from high-energy particles.

III. Technical Key Points and Challenges of HJT-Specific PVD

1. Low-Temperature Process

The amorphous silicon film in HJT cells is extremely temperature-sensitive, typically requiring the entire process chain to remain below 200°C. Therefore, the PVD process must strictly control thermal loading to prevent plasma overheating, which can degrade the amorphous silicon layer's performance (hydrogen outgassing, structural changes).

2. Balancing Film Properties

TCO films require an optimal balance between conductivity and transparency.

Conductivity is determined by carrier concentration and mobility. Carrier concentration is typically enhanced through doping (e.g., Sn in ITO, Zn in IZO) and introducing trace hydrogen during deposition to increase oxygen vacancies.

Transparency demands high transmittance across the visible and near-infrared spectrum. Excessively high carrier concentration induces free carrier absorption in the infrared region, leading to parasitic absorption losses.

Process optimization objective: Identify the optimal process window that maximizes the product of “conductivity × transmittance.”

3. Step Coverage and Damage Control

The surface of HJT cells features a textured structure with micrometer-scale pyramids. PVD requires excellent step coverage on these pyramids to ensure continuous, uniform TCO film coverage across the entire textured surface; otherwise, conductive dead zones will form.

High-energy particles (including reflected argon atoms, secondary electrons, etc.) bombarding the silicon wafer surface may cause “sputtering damage” to the underlying amorphous silicon interface, increasing interface state density and affecting open-circuit voltage. Damage mitigation requires adjusting process parameters such as working pressure, power, and bias voltage.

4. Common TCO Targets

ITO: Indium Tin Oxide, the longest-established material with balanced performance, but indium is expensive and toxic.

IWO/IWO:H: Indium tungsten oxide, featuring higher mobility and lower free carrier absorption at equivalent conductivity. Particularly suited for HJT cells, enabling higher short-circuit current.

IZO: Indium zinc oxide, also an important indium-free or low-indium alternative.

IV. Brief Comparison of PVD and RPD

In the HJT field, another crucial technique for depositing TCO is Reactive Plasma Deposition (RPD). RPD generates TCO films by reacting an oxygen plasma with organometallic sources, enabling superior film properties at lower temperatures—particularly advantageous in minimizing interface damage.

Principle Differences: RPD utilizes arc discharge to evaporate target materials into plasma. This plasma is then guided and filtered by electromagnetic fields to deposit low-energy, high-ionization-rate plasma onto the substrate.

Advantages: Films deposited by RPD exhibit minimal damage and typically higher carrier mobility, enhancing performance.

Disadvantages: High equipment cost, low target material utilization, significant maintenance expenses, and patent barriers.

Current Status: PVD remains the dominant technology in HJT production lines due to its maturity, cost advantages, and balanced performance; RPD finds application in scenarios pursuing extreme efficiency.

The PVD process for HJT cells fundamentally utilizes magnetron sputtering—a physical vapor deposition technique—to deposit TCO films with high electrical conductivity and high light transmittance onto sensitive amorphous silicon layers under low-temperature, vacuum conditions. This process perfectly balances the three critical functions of “conductivity,” “light transmission,” and “protection,” serving as the vital bridge connecting photogenerated carriers within the cell to the external circuit. The level of process mastery directly determines the ultimate efficiency and cost of HJT cells.