Quantum Efficiency Tester

PL/EL Integrated System

PV-Reflectumeter

3D Confocal Microscope

In-Line Four Point Probe Tester

Four Point Probe Tester

In-Line Thin Film Thickness Tester

Raman Spectrometer

FTIR Spectrometer

Spectrophotometer

Automatic Spectroscopic Ellipsometer

Contact Resistance Tester

Ultra depth of field 3D microscope

Auto Visual Tester

VMM PV Vision Measuring Machine

Solar Cell Horizontal Tensile Tester

Steady State Solar Simulator for Solar Cell

Solar Cell UV Aging Test Chamber

Solar Cell Comprehensive Tensile Tester

Visual Inspection Tester

Wet Leakage Current Tester

PV Module EL Tester

PV Module UV Preconditioning Chamber

Steady State Solar Simulator for PV Module

Current Continuous Monitor

Potential Induced Degradation Test

Bypass Diode Tester

LeTID Test System

Reverse Current Overload Tester

Impulse Voltage Tester

Hipot Insulation Tester

Ground Continuity Tester

Hipot Insulation Ground Tester

Damp Heat Test Chamber

Humidity Freeze Test

Thermal Cycle Test Chamber

Dynamic Mechanical Load Tester

Static Mechanical Load Tester

Hail Impact Tester

Robustness of Termination Tester

Module Breakage Tester

Cut Susceptibility Tester

Peel Shear Strength Tester

Universal Testing Machine (Single-arm)

Universal Testing Machine (Double-arm)

Glass Transmittance Tester

Acetic Acid Test Chamber

EVA Degree of Crosslinking Test System

Junction Box Comprehensive Tester

Drop ball tester

Semi-automatic scanning four-probe tester

Stylus Profilometer

Maximum Power Point Tracker

Perovskite Glass Transmittance Tester

Perovskite P1 Laser Scribing Multifunctional Testing Machine

Perovskite Online PL Tester

Perovskite Online Sheet Resistance Tester

Online Perovskite Film Thickness Tester

Perovskite Process Inspection Workstation

Portable IV Curve Tester

Portable EL Tester

Portable Thermal Imaging Tester

Solar Module Multi-Channel Testing System

PV Inverter Power Quality Tester

Drone EL Tester

IV Tester

IVEL Cell Sorting Machine

Passivation Mechanism of Al₂O₃ Films

Date : 26 December 2025Views : 220

The passivation of aluminum oxide films can be categorized into chemical passivation and field-effect passivation. Chemical passivation involves forming a dense oxide layer on the film surface, effectively suppressing non-radiative recombination of charge carriers and enhancing chemical stability at the interface. Field-effect passivation regulates the interface band structure using fixed charges, thereby inhibiting the accumulation of minority carriers on the surface. The combined action of these two mechanisms significantly reduces surface recombination rates, improving the cell's open-circuit voltage and conversion efficiency.

The passivation mechanism of aluminum oxide films in solar cells manifests primarily through two aspects: chemical passivation and field-effect passivation. This dual passivation mechanism is the key reason why aluminum oxide (Al₂O₃) thin films, particularly in crystalline silicon solar cells, achieve exceptional surface passivation performance.

I. Chemical Passivation

Chemical passivation

1. Core Function

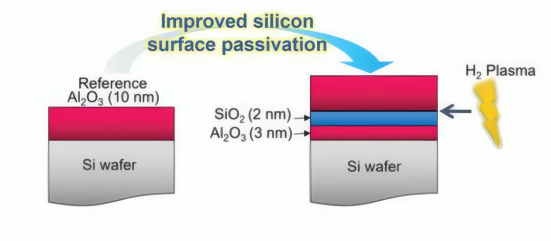

To effectively reduce the number of exposed dangling bonds on silicon wafer surfaces, various surface treatment technologies can be employed. Specific methods include hydrogen passivation, oxidation passivation, or chemical modification. These processes form stable chemical bonds, saturating the active sites on the silicon surface and significantly lowering the density of dangling bonds on the material's surface. Such surface modifications not only enhance the material's electrical properties but also improve device interface characteristics, playing a crucial role in semiconductor device manufacturing and performance optimization.

2. Principle

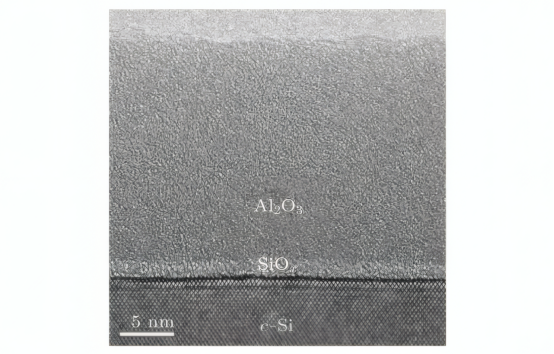

TEM image of a 20nm-thick Al₂O₃ film on monocrystalline silicon

Silicon crystal surfaces contain numerous exposed, unsaturated chemical bonds (dangling bonds). These dangling bonds introduce interface states within the silicon bandgap that facilitate carrier recombination. When a high-quality Al₂O₃ film is deposited onto the silicon surface (typically achieved via atomic layer deposition), aluminum and oxygen atoms in the film react with the silicon surface's dangling bonds, forming stable Si-O-Al or Si-Al bonds. These chemical bonds effectively “saturate” the dangling bonds on the silicon surface, significantly reducing the density of interface states. This, in turn, minimizes non-radiative recombination (Shockley-Read-Hall recombination) of charge carriers at the surface.

3. Effect

Advanced surface repair technologies can effectively eliminate both microscopic defects and macroscopic damage on material surfaces. Surface imperfections such as scratches, pits, and microcracks fall within the scope of repair. This direct repair method significantly optimizes the physicochemical properties of material surfaces, substantially reducing the rate of interfacial recombination processes. Specifically, the repaired surface forms a more uniform and dense protective layer, decreasing the number of active sites and effectively suppressing electron-hole recombination at the interface. Simple to implement and highly effective, this approach provides a practical solution for enhancing material interface performance and overall stability.

II. Field-Effect Passivation

1. Core Mechanism

In the near-surface region of semiconductor silicon materials, an artificially controllable electric field is induced by applying an external bias or constructing a space charge region. This directional electric field exerts a pronounced repulsive or attractive effect on minority carriers (e.g., holes in n-type silicon or electrons in p-type silicon). Through this charge regulation mechanism, minority carriers are effectively driven away from surface regions with high recombination activity, significantly reducing surface recombination rates. This electric field modulation technique enables precise control over carrier spatial distribution, providing an effective means to optimize device surface passivation.

2. Principle

Al₂O₃ films harbor substantial fixed negative charges, typically originating from charge centers within the film—such as defects associated with oxygen vacancies or aluminum vacancies—and inherent material properties.

This fixed charge density is exceptionally high, typically ranging from 10¹² to 10¹³ cm⁻² (far exceeding the positive charge density of SiO₂).

When Al₂O₃ is deposited on p-type silicon (the most common application scenario, e.g., the rear side of PERC cells): the fixed charges induce a positively charged hole accumulation layer (i.e., the accumulation layer) near the p-type silicon surface. Simultaneously, the electric field generated by these charges repels minority carriers (electrons), pushing them away from the silicon/Al₂O₃ interface.

When Al₂O₃ is deposited on n-type silicon: the fixed negative charge induces a negatively charged electron accumulation layer (i.e., the accumulation layer) near the n-type silicon surface. Simultaneously, the electric field generated by this charge attracts minority carriers (holes) toward the interface (an undesirable effect). Consequently, the passivation effect of Al₂O₃ on n-type silicon is typically less effective than on p-type silicon.

3. Effect

For p-type silicon, driving minority carriers (electrons) away from surfaces with high recombination rates significantly reduces electron concentration at the surface, thereby markedly lowering surface recombination rates.

For n-type silicon, attracting minority carriers (holes) to the surface may increase recombination (resulting in poor performance or requiring special treatment).

III. Synergistic Effects of Chemical Passivation and Field-Effect Passivation

On p-type silicon substrate materials (particularly applicable to the typical process scenario of PERC solar cell rear passivation), the outstanding passivation performance of Al₂O₃ films primarily manifests as a dual synergistic effect between chemical passivation mechanisms and field-effect passivation mechanisms. At the microscopic level, the chemical passivation process primarily relies on the stable Si-O covalent bond structure spontaneously formed at the Al₂O₃ film/silicon substrate interface. This structure effectively neutralizes and eliminates recombination centers such as dangling bonds at the interface (significantly reducing the density of interface states). Concurrently, the field-effect passivation mechanism leverages the inherent fixed negative charge properties of the Al₂O₃ film to induce the formation of an accumulation layer on the silicon surface. This layer significantly suppresses the diffusion flux of minority carriers (electrons in this case) toward the surface region.

These two physical mechanisms do not operate independently but produce synergistic enhancement through charge compensation and band structure regulation. Chemical passivation improves interface quality, creating favorable conditions for field-effect passivation; conversely, field-effect passivation further alleviates interface recombination pressure by reducing carrier concentration gradients. It is precisely this complementary interaction that enables the Al₂O₃ passivation layer on p-type silicon surfaces to simultaneously achieve a surface recombination rate below 10 cm/s and an effective carrier lifetime exceeding 1 ms. These performance metrics play a decisive role in enhancing the photovoltaic conversion efficiency of solar cells.

IV. Characterization of Al₂O₃ Passivation Effect

Low Surface Recombination Rate: Direct indicator of superior passivation performance.

High Effective Minority Carrier Lifetime: Determined through quasi-steady-state photocathode measurements or microwave photocathode decay techniques.

High open-circuit voltage: In final solar cell devices, superior rear passivation significantly enhances cell open-circuit voltage.

High built-in potential/field effect: Capacitance-voltage testing reveals elevated fixed negative charge density at the Al₂O₃/Si interface.

The passivation mechanism of alumina films in solar cells manifests as the perfect synergy between chemical passivation and field-effect passivation. Chemical passivation refers to reducing recombination centers by saturating dangling bonds on the silicon surface and lowering the density of interface states. Field-effect passivation involves repelling minority carrier electrons away from the surface of p-type silicon through the repulsive force exerted by high-density fixed negative charges. This dual mechanism makes Al₂O₃ an ideal passivation material for achieving ultra-low surface recombination rates on p-type silicon surfaces. It has played a transformative role, particularly in the back-side passivation of PERC cells, significantly enhancing cell efficiency. Its exceptional passivation performance depends on high-quality film deposition (especially atomic layer deposition (ALD) technology) and appropriate post-processing techniques.