Quantum Efficiency Tester

PL/EL Integrated System

PV-Reflectumeter

3D Confocal Microscope

In-Line Four Point Probe Tester

Four Point Probe Tester

In-Line Thin Film Thickness Tester

Raman Spectrometer

FTIR Spectrometer

Spectrophotometer

Automatic Spectroscopic Ellipsometer

Contact Resistance Tester

Ultra depth of field 3D microscope

Auto Visual Tester

VMM PV Vision Measuring Machine

Solar Cell Horizontal Tensile Tester

Steady State Solar Simulator for Solar Cell

Solar Cell UV Aging Test Chamber

Solar Cell Comprehensive Tensile Tester

Visual Inspection Tester

Wet Leakage Current Tester

PV Module EL Tester

PV Module UV Preconditioning Chamber

Steady State Solar Simulator for PV Module

Current Continuous Monitor

Potential Induced Degradation Test

Bypass Diode Tester

LeTID Test System

Reverse Current Overload Tester

Impulse Voltage Tester

Hipot Insulation Tester

Ground Continuity Tester

Hipot Insulation Ground Tester

Damp Heat Test Chamber

Humidity Freeze Test

Thermal Cycle Test Chamber

Dynamic Mechanical Load Tester

Static Mechanical Load Tester

Hail Impact Tester

Robustness of Termination Tester

Module Breakage Tester

Cut Susceptibility Tester

Peel Shear Strength Tester

Universal Testing Machine (Single-arm)

Universal Testing Machine (Double-arm)

Glass Transmittance Tester

Acetic Acid Test Chamber

EVA Degree of Crosslinking Test System

Junction Box Comprehensive Tester

Drop ball tester

Semi-automatic scanning four-probe tester

Stylus Profilometer

Maximum Power Point Tracker

Perovskite Glass Transmittance Tester

Perovskite P1 Laser Scribing Multifunctional Testing Machine

Perovskite Online PL Tester

Perovskite Online Sheet Resistance Tester

Online Perovskite Film Thickness Tester

Perovskite Process Inspection Workstation

Portable IV Curve Tester

Portable EL Tester

Portable Thermal Imaging Tester

Solar Module Multi-Channel Testing System

PV Inverter Power Quality Tester

Drone EL Tester

IV Tester

IVEL Cell Sorting Machine

LECO Process for TOPCon Cells

Date : 9 January 2026Views : 195

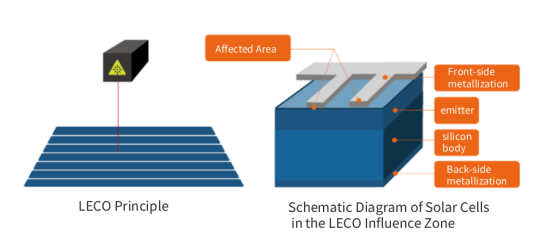

Within the realm of crystalline silicon solar cell technology, the LECO (Laser-Enhanced Contact Optimization) process for TOPCon (Tunnel Oxide Contact) cells represents a critical back-end processing technique. This process employs high-precision, controllable laser processing to target the contact interface between the cell's metal electrodes and the silicon substrate, achieving microstructural optimization and significant functional enhancement. Through localized, precise energy injection and material modification, LECO effectively modulates the barrier properties at the contact interface, reduces contact resistance, and substantially improves both physical adhesion and electrical compatibility at the interface. This process not only significantly enhances the cell's conversion efficiency, open-circuit voltage, and fill factor but also boosts the module's long-term operational stability and reliability. Furthermore, LECO technology optimizes selective carrier transport by minimizing carrier recombination losses at the interface.

I. Process Principle

LECO Process Principle

LECO stands for Laser-Enhanced Contact Optimization. Its core principle involves utilizing localized laser energy to precisely optimize the contact area between metal electrodes (silver paste) and silicon substrates without compromising the passivation effect in non-contact regions.

1. Challenges of Traditional Processes

In high-efficiency cells (e.g., TOPCon, HJT), the surface doping layers (emitter or passivation layer) are extremely thin and precise to achieve high open-circuit voltage. Traditional thermal sintering involves global heating, which often leads to overburning or burn-through during metal-semiconductor contact formation. This damages the shallow junction passivation layer, increasing carrier recombination and limiting cell efficiency.

2. LECO's Solution

1) Printing and Pre-Sintering: First, silver paste electrodes are screen-printed onto the cell surface as in conventional processes, followed by low-temperature pre-sintering to initially solidify the silver paste.

2) Laser Scanning: This is the critical step. A laser of a specific wavelength (typically green or infrared) precisely scans directly beneath the silver electrode lines. The laser energy is selectively absorbed by the silicon substrate, generating localized, instantaneous high temperatures (reaching thousands of degrees Celsius) at the electrode-silicon interface.

3) Interface Reaction and Contact Formation: This extreme heat triggers vigorous physicochemical reactions between the glass frit and metallic silver particles in the paste with the underlying silicon:

· Etching through the surface anti-reflective coating and passivation layer.

· Forming an alloy between silver and silicon at the interface, creating numerous, uniformly distributed silver-silicon eutectic contact points.

4) Post-Processing: An additional low-temperature thermal treatment is sometimes performed to stabilize the contact points and optimize conductivity.

II. Key Process Parameters

Application of LECO Process in TOPCon Cells

The overall performance and final treatment results of the LECO process are highly dependent on the precise control and strict management of the following critical process parameters. These parameters not only directly impact process stability and repeatability but also decisively influence the quality and performance of the final product.

1. Laser Parameters

· Wavelength: Typically 532nm green laser or 1064nm infrared laser. Green laser exhibits higher absorption in silicon and silver paste, yielding superior results.

· Power: One of the most critical parameters. Insufficient power fails to form effective contacts, resulting in high resistance; excessive power risks burning the silicon substrate, causing edge chipping or electrode fracture.

· Spot Size and Shape: Must match electrode width to ensure energy concentration beneath the electrode.

· Scan Speed: Together with laser power, determines the energy density per unit area. Excessively high speed results in insufficient energy; excessively low speed may cause overburning.

· Pulse Frequency and Overlap Rate: For pulsed lasers, pulse frequency and spot movement overlap rate must be optimized to ensure contact uniformity and continuity.

2. Silver Paste Characteristics

The silver paste employed in the Laser-Excited Contact (LECO) process is a specially formulated material with a deeply optimized composition. Specifically:

- The glass component within the silver paste system is precisely controlled to exhibit ideal melting and wetting behavior under laser irradiation.

- The organic carrier possesses excellent rheological properties and volatility, facilitating paste shaping during processing and subsequent de-gassing operations. The morphology of silver particles is specially engineered—such as spherical or flake-shaped silver powders—to increase specific surface area and enhance sintering activity. This significantly boosts laser energy absorption efficiency and reactivity, ensuring superior electrode formation quality and electrical performance.

3. Process Environment

Certain LECO processes require execution under strictly controlled atmospheric conditions, such as within protective inert gas atmospheres like nitrogen. This atmosphere control effectively prevents oxidation of the silver paste and wafer surfaces during high-temperature laser processing, thereby improving the metallurgical quality and bonding strength at the contact interface. Furthermore, specific atmospheres help optimize the sintering behavior of the silver paste and the uniformity of contact resistance, resulting in electrodes with more consistent electrical properties and higher reliability. This is particularly advantageous for manufacturing high-efficiency solar cells.

III. Efficiency Enhancement Mechanism

As an advanced solar cell manufacturing technology, the LECO process (Laser-Enhanced Contact Optimization) significantly improves cell conversion efficiency through several key pathways. First, this process utilizes high-precision laser technology to optimize the microstructure of the metal electrodes on the cell surface, effectively reducing contact resistance and minimizing energy loss during transmission. Second, LECO enhances carrier collection efficiency within the light-absorbing layer by optimizing the interface characteristics between electrodes and semiconductor materials, facilitating efficient separation and transport of electrons and holes. Additionally, this technology improves surface passivation, reducing surface recombination losses and further boosting overall cell performance.

1. Significantly Enhances Filling Factor

The primary contribution lies in LECO forming more numerous and uniform silver-silicon contact points, drastically reducing the metal-semiconductor contact resistivity. Lower series resistance directly translates to higher FF, typically yielding an absolute efficiency gain of 0.3%-0.8%.

2. Enhanced or Maintained Open-Circuit Voltage

By preventing global high-temperature sintering from damaging the passivation layer, the LECO process perfectly preserves passivation quality in the inter-electrode regions. This effectively suppresses carrier recombination rates at the surface, thereby maintaining or even slightly increasing Voc.

3. Potential Increase in Short-Circuit Current

The optimized cell operating point results from maintaining Voc and enhancing FF. Simultaneously, improved contact reduces current transmission losses, exerting a slight positive effect on Isc.

In summary, LECO's efficiency enhancement mechanism achieves a significant leap in FF by substantially optimizing contact quality—without sacrificing (and potentially enhancing) Voc.