Quantum Efficiency Tester

PL/EL Integrated System

PV-Reflectumeter

3D Confocal Microscope

In-Line Four Point Probe Tester

Four Point Probe Tester

In-Line Thin Film Thickness Tester

Raman Spectrometer

FTIR Spectrometer

Spectrophotometer

Automatic Spectroscopic Ellipsometer

Contact Resistance Tester

Ultra depth of field 3D microscope

Auto Visual Tester

VMM PV Vision Measuring Machine

Solar Cell Horizontal Tensile Tester

Steady State Solar Simulator for Solar Cell

Solar Cell UV Aging Test Chamber

Solar Cell Comprehensive Tensile Tester

Visual Inspection Tester

Wet Leakage Current Tester

PV Module EL Tester

PV Module UV Preconditioning Chamber

Steady State Solar Simulator for PV Module

Current Continuous Monitor

Potential Induced Degradation Test

Bypass Diode Tester

LeTID Test System

Reverse Current Overload Tester

Impulse Voltage Tester

Hipot Insulation Tester

Ground Continuity Tester

Hipot Insulation Ground Tester

Damp Heat Test Chamber

Humidity Freeze Test

Thermal Cycle Test Chamber

Dynamic Mechanical Load Tester

Static Mechanical Load Tester

Hail Impact Tester

Robustness of Termination Tester

Module Breakage Tester

Cut Susceptibility Tester

Peel Shear Strength Tester

Universal Testing Machine (Single-arm)

Universal Testing Machine (Double-arm)

Glass Transmittance Tester

Acetic Acid Test Chamber

EVA Degree of Crosslinking Test System

Junction Box Comprehensive Tester

Drop ball tester

Semi-automatic scanning four-probe tester

Stylus Profilometer

Maximum Power Point Tracker

Perovskite Glass Transmittance Tester

Perovskite P1 Laser Scribing Multifunctional Testing Machine

Perovskite Online PL Tester

Perovskite Online Sheet Resistance Tester

Online Perovskite Film Thickness Tester

Perovskite Process Inspection Workstation

Portable IV Curve Tester

Portable EL Tester

Portable Thermal Imaging Tester

Solar Module Multi-Channel Testing System

PV Inverter Power Quality Tester

Drone EL Tester

IV Tester

IVEL Cell Sorting Machine

Efficiency Reaches 34.6%! Analysis of Perovskite/Silicon Tandem Cell Fabrication Processes and Industrial Applications

Date : 13 January 2026Views : 240

Perovskite/silicon tandem solar cells have become a key pathway for enhancing the sustainability of photovoltaic systems by breaking the efficiency limits of single-junction cells. Despite zero emissions during operation, environmental challenges such as material toxicity, stability, and recycling persist throughout their lifecycle. This paper focuses on the life cycle assessment and sustainability characteristics of this technology. Leveraging precise spectral response measurements from the Millennial QE Quantum Efficiency Tester, it systematically analyzes structural design, efficiency advancements, environmental impacts, and economic viability. By synergistically addressing efficiency, stability, and environmental compatibility, it provides foundational support for the sustainable development of future photovoltaic technologies.

Overview of Perovskite/Silicon Tandem Solar Cells

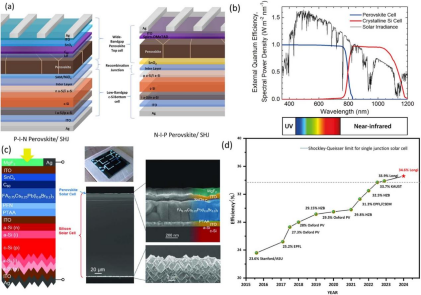

(a) Schematic of N-I-P and P-I-N perovskite/silicon tandem solar cells; (b) Spectral response of perovskite top cell and c-Si bottom cell; (c) Cross-sectional SEM image of tandem cell, with magnified views of perovskite top cell and silicon back texture; (d) Efficiency evolution of perovskite/silicon tandem solar cells

Structure and Operating Principle

Perovskite/silicon tandem cells typically consist of a perovskite top cell and a crystalline silicon bottom cell. From a spectral absorption perspective, the perovskite top cell's wide bandgap (1.7–1.8 eV) enables efficient absorption and conversion of high-energy photons (short-wavelength light), while the monocrystalline silicon bottom cell (1.12 eV) captures and converts low-energy photons (long-wavelength light), thereby minimizing thermalization losses and spectral losses. The two cells are connected in series or parallel, requiring precise current matching to optimize overall performance.

Material Architecture

The p-i-n perovskite top cell comprises a hole transport layer (HTL), perovskite light-absorbing layer, electron transport layer (ETL), transparent conductive oxide (TCO) layer, and metal gate. The highest-efficiency perovskite/silicon tandem cells currently employ TOPCon or HJT monocrystalline silicon cells as the bottom layer. These bottom cells feature a 1-3 micrometer (μm) pyramidal texture on their surface, significantly enhancing light absorption efficiency.

Efficiency Progress

Technological advancements have accelerated in recent years: short-circuit current reached 20.56 mA/cm² in 2018, while efficiency records hit 34.6% by 2024. Fabrication processes evolved from solution-based methods to evaporation and hybrid techniques, improving texture surface coverage and cell performance. These achievements fully demonstrate the rapid development potential of perovskite/silicon tandem solar cells.

Life Cycle Assessment and Environmental Impact of Perovskite/Silicon Tandem Solar Cells

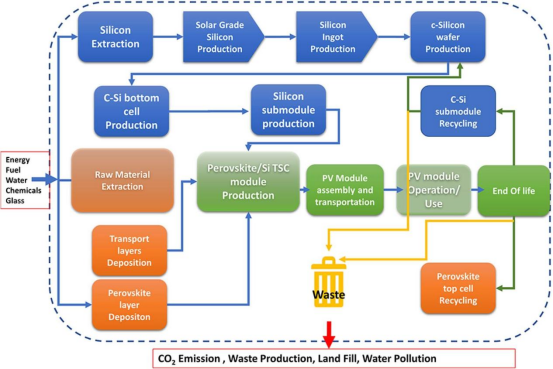

Schematic Diagram of the Closed-Loop Recycling Process for Perovskite/Silicon Tandem Solar Cells

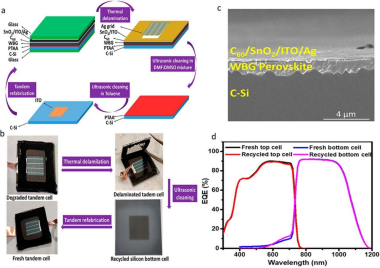

(a) Schematic diagram of the recycling process for silicon-based cells; (b) Schematic diagram of the recycling and remanufacturing process for tandem solar cells; (c) SEM cross-sectional image of a remanufactured tandem device; (d) J-V curves and EQE (external quantum efficiency) spectra of newly fabricated and remanufactured tandem devices.

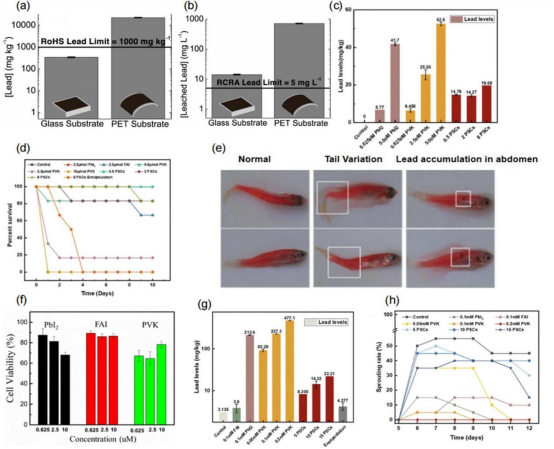

(a) Total lead concentration in perovskite films on glass and PET substrates; (b) Lead leaching concentration in perovskite films on glass and PET substrates under TCLP (Toxic Characteristic Leaching Procedure); (c) Lead content in zebrafish after 10 days of cultivation; (d) Survival rate of zebrafish over 10 days under different growth conditions; (e) Growth status of zebrafish with and without FAPbI₃ addition; (f) Specific mortality data of chondrocytes at different perovskite material concentrations; (g) Lead concentration in radish samples under different conditions; (h) Germination rate of Arabidopsis at different time points.

Assessment Methodology

Life Cycle Assessment (LCA) follows the ISO 14040 and 14044 standard framework, comprising four stages:

- Objective and Scope Definition (clarifying assessment goals and parameters)

- Life Cycle Inventory Analysis (LCI, collecting energy, material input, and environmental emission data)

- Life Cycle Impact Assessment (LCIA, analyzing potential environmental impacts based on inventory data)

- Result Interpretation (analyzing conclusions to guide decision-making and identify improvement directions) The IEA PVPS guidelines are referenced to ensure assessment consistency and credibility.

Environmental Impact Analysis

Material Phase: Wafer production exhibits high energy consumption (~3534 MJ/m²) and is a primary contributor to global warming potential (GWP). Perovskite top cell manufacturing has lower energy consumption (188 MJ/m²), but the carbon footprint is influenced by the electricity source.

Lead Usage Concerns: Perovskite contains approximately 0.4 g/m² of lead, below RoHS limits. However, TCLP testing indicates lead leaching exceeds U.S. EPA standards, requiring specialized handling.

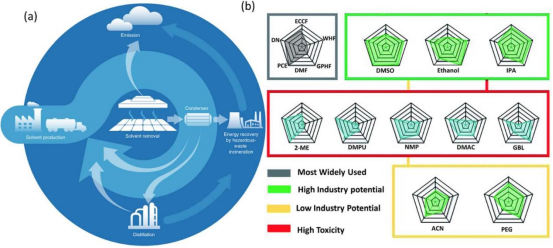

Chemical Management: Toxic solvents used in manufacturing processes (e.g., DMF) require proper management, with low-toxicity alternatives such as DMSO and ethanol recommended.

Waste Disposal: Efficient end-of-life (EOL) management is key to reducing the environmental impact of perovskite/silicon tandem cells. Effective recycling of silicon and perovskite materials enables reuse of critical components and waste reduction. Advancements in recycling technologies and the establishment of closed-loop systems can further enhance the sustainability of tandem cell technology.

Comparative Analysis

Compared to single-junction c-Si cells, perovskite/silicon tandem cells offer higher efficiency, shorter energy payback time (EPBT), and lower environmental impact per unit of electricity generated. However, the absolute environmental impact per module may be higher, necessitating compensation through improved efficiency and longevity.

Sustainability Analysis of Perovskite/Silicon Tandem Solar Cells

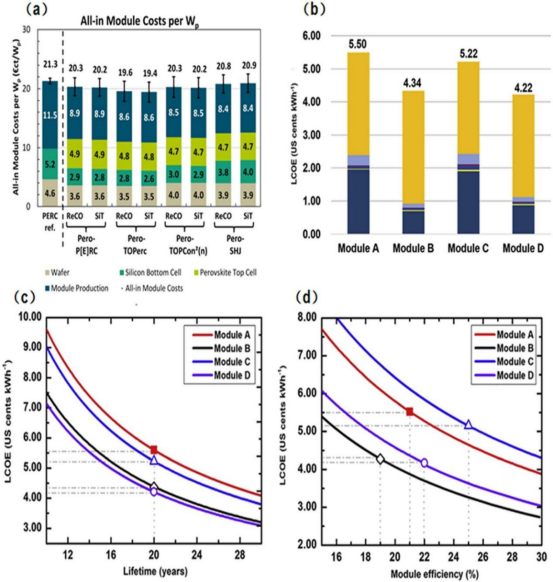

(a) Comparison of total module cost per peak watt (Wp) for all perovskite-silicon tandem concepts in Figure 4 versus a conventional PERC single-junction reference cell (left); (b) Levelized cost of electricity (LCOE) comparison; (c) Module lifetime; (d) Sensitivity analysis of efficiency

(a) Schematic of LCA system boundaries illustrating potential perovskite PV production pathways; (b) Five-dimensional property map of solvents, where higher saturation indicates greater commercialization potential

Economic Assessment

The manufacturing cost of perovskite/silicon tandem cells is influenced by materials, processes, and scale. Analysis indicates that this technology becomes market-competitive when efficiency exceeds 26%, costs are controlled between 90-150 USD/m², and stability matches that of c-Si. LCOE analysis indicates that tandem cells can achieve lower costs than single-junction c-Si cells (5.22 vs. 5.50 US cents/kWh), provided annual degradation rates are controlled within 1-3%.

Toxicity Analysis and Management

Lead Management Strategies: Techniques like epoxy encapsulation and EVA films reduce lead leakage; chemical recycling achieves 99.2% lead recovery rates.

Lead-Free Alternatives: Tin-based perovskites exhibit lower toxicity but insufficient efficiency, while tin itself poses environmental risks.

Green Processes: Low-toxicity solvents such as DMSO and ethanol are recommended to mitigate environmental and health hazards during manufacturing.

Challenges and Outlook

Technical Challenges

Stability and Durability: Improving perovskite materials' tolerance to humidity, oxygen, high temperatures, and ultraviolet radiation.

Interface Optimization: Enhancing the interface between charge transport layers and perovskite/c-Si to minimize recombination losses.

Material Sustainability: Ensuring sustainable supply and recycling of critical materials such as silver and indium.

Policy Support

Establishing a comprehensive policy framework—including R&D support, recycling standards, and fiscal incentives—is essential to advance perovskite/silicon tandem cell commercialization. Consumer education and demonstration projects will also boost market acceptance.

Circular Economy

Developing closed-loop recycling designs, material reuse technologies, and industry collaboration mechanisms are vital pathways to sustainable PV industry development. Efficient recycling technologies for perovskite and silicon materials require further R&D.

Perovskite/silicon tandem solar cells hold significant potential for enhancing efficiency and reducing environmental impact, yet they still face challenges such as stability, toxicity management, and recycling. Through material innovation, process optimization, policy support, and circular economy strategies, this technology is poised to become a vital component of future sustainable energy systems. Future research should focus on long-life design, lead-free materials, green manufacturing, and full life-cycle management to advance its commercialization.

Millennial QE Quantum Efficiency Tester

The Millennial QE Quantum Efficiency Tester measures the spectral response of solar cells and diagnoses areas with low spectral response through quantum efficiency analysis. It offers universal compatibility, a broad spectral measurement range, testing accuracy, and traceability.

email:market@millennialsolar.com

Compatible with all solar cell types to meet diverse testing needs

Spectral range up to 300-2500nm with customizable options

Dual light source structure (xenon lamp + halogen lamp) ensures light source stability

Through precise measurement and analysis of the spectral response of perovskite top cells and silicon bottom cells, the Millennial QE Quantum Efficiency Tester provides critical data support for optical matching and current balancing in tandem structures. This significantly enhances solar spectrum utilization efficiency and overall photovoltaic conversion performance.

Related Products