Quantum Efficiency Tester

PL/EL Integrated System

PV-Reflectumeter

3D Confocal Microscope

In-Line Four Point Probe Tester

Four Point Probe Tester

In-Line Thin Film Thickness Tester

Raman Spectrometer

FTIR Spectrometer

Spectrophotometer

Automatic Spectroscopic Ellipsometer

Contact Resistance Tester

Ultra depth of field 3D microscope

Auto Visual Tester

VMM PV Vision Measuring Machine

Solar Cell Horizontal Tensile Tester

Steady State Solar Simulator for Solar Cell

Solar Cell UV Aging Test Chamber

Solar Cell Comprehensive Tensile Tester

Visual Inspection Tester

Wet Leakage Current Tester

PV Module EL Tester

PV Module UV Preconditioning Chamber

Steady State Solar Simulator for PV Module

Current Continuous Monitor

Potential Induced Degradation Test

Bypass Diode Tester

LeTID Test System

Reverse Current Overload Tester

Impulse Voltage Tester

Hipot Insulation Tester

Ground Continuity Tester

Hipot Insulation Ground Tester

Damp Heat Test Chamber

Humidity Freeze Test

Thermal Cycle Test Chamber

Dynamic Mechanical Load Tester

Static Mechanical Load Tester

Hail Impact Tester

Robustness of Termination Tester

Module Breakage Tester

Cut Susceptibility Tester

Peel Shear Strength Tester

Universal Testing Machine (Single-arm)

Universal Testing Machine (Double-arm)

Glass Transmittance Tester

Acetic Acid Test Chamber

EVA Degree of Crosslinking Test System

Junction Box Comprehensive Tester

Drop ball tester

Semi-automatic scanning four-probe tester

Stylus Profilometer

Maximum Power Point Tracker

Perovskite Glass Transmittance Tester

Perovskite P1 Laser Scribing Multifunctional Testing Machine

Perovskite Online PL Tester

Perovskite Online Sheet Resistance Tester

Online Perovskite Film Thickness Tester

Perovskite Process Inspection Workstation

Portable IV Curve Tester

Portable EL Tester

Portable Thermal Imaging Tester

Solar Module Multi-Channel Testing System

PV Inverter Power Quality Tester

Drone EL Tester

IV Tester

IVEL Cell Sorting Machine

Summary of Reliability Testing for Crystalline Silicon Solar Cells

Date : 16 January 2026Views : 170

High-efficiency crystalline silicon solar cell reliability testing aims to comprehensively evaluate the performance stability and environmental adaptability of cells during long-term operation. This testing encompasses multiple critical components, including mechanical load testing, thermal cycling testing, freeze-thaw testing, and potential-induced degradation (PID) testing. By simulating extreme climatic conditions and complex operational scenarios, it verifies the cells' resistance to degradation under combined stresses of humidity, temperature, and voltage. This ensures sustained high power output and structural integrity throughout their lifecycle, thereby providing robust technical assurance for the long-term stable operation of photovoltaic systems.

Core Test Types and Mechanisms

The following outlines the fundamental differences between LID, LeTID, CID, PID, TC, DH, and UV from three dimensions: degradation triggers, core mechanisms, and affected components.

1. LID (Light-Induced Degradation)

• Trigger: Light exposure (primarily AM1.5 spectrum).

• Mechanism: Primarily occurs in boron-doped p-type silicon cells. Under illumination, boron (B) in the silicon wafer combines with interstitial oxygen (Oi) to form boron-oxygen complexes (Bs-Oi). These complexes act as highly efficient recombination centers, significantly reducing minority carrier (electron) lifetime, leading to decreased short-circuit current (Isc) and fill factor (FF).

• Characteristics: Rapid decay rate (most pronounced within the first 100 hours), partially reversible (high-temperature annealing decomposes boron-oxygen complexes, restoring efficiency).

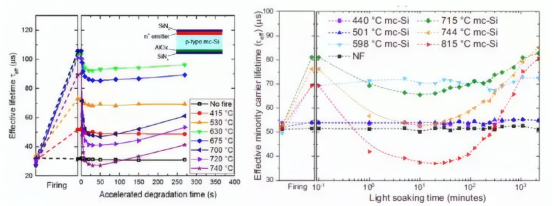

2. LeTID (Light and Elevated Temperature Induced Degradation)

Effect of Sintering Temperature on LeTID

• Triggers: Light exposure + elevated temperature (40–80°C, typically 60°C).

• Mechanism: Primarily affects p-type PERC cells, centered on hydrogen (H) migration and defect activation. Photogenerated carriers (electron-hole pairs) from illumination promote hydrogen diffusion from passivation layers (e.g., AlOx/SiNx) into the silicon substrate. Hydrogen combines with lattice defects (e.g., vacancies, metallic impurities) to form new recombination centers (e.g., Si-H bond cleavage, metal hydrides), leading to reduced minority carrier lifetime.

• Characteristics: The degradation process is slower than LID (100–1000 hours), exhibits a “degradation-recovery” phenomenon (partial recovery occurs upon stopping illumination/increasing temperature), and is more difficult to eliminate than LID.

3. CID (Carrier Injection Degradation)

• Cause: Carrier injection (either photoinjection or electroinjection, distinct from simple illumination).

• Mechanism: Broadly refers to the process where injected carriers (electrons/holes) activate defects. It can be viewed as an “extended version” of LeTID—where LeTID involves “photo-injected carriers + high temperature,” while CID emphasizes the “injection of carriers” itself (regardless of photo- or electro-injection). The core mechanism involves carrier injection providing energy to promote hydrogen migration or movement of lattice defects (e.g., vacancies, interstitial atoms), forming recombination centers (e.g., metal impurity diffusion, silicon-hydrogen bond breaking).

Photo-injected CID: LeTID (photo-generated carrier injection);

Electro-injected CID: Carrier injection via applied bias (e.g., forward current) directly activates defects without illumination.

• Characteristics: Closely related to cell type (p-type/n-type), doping concentration, and hydrogen content. Currently dominated by research-level testing with no unified standards.

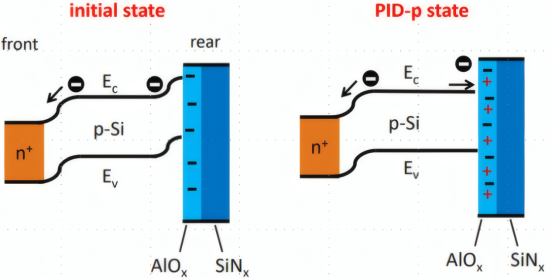

4.PID (Potential Induced Degradation)

PID Schematic Diagram

• Cause: High voltage difference (between the module and the ground terminal, typically ±500V to ±1500V).

• Mechanism: Under high voltage, mobile ions like sodium ions (Na+) in the glass migrate toward the cell surface under the influence of the electric field. These ions deposit on the SiNx passivation layer or PN junction, forming conductive pathways or surface recombination layers. This leads to a decrease in shunt resistance (Rsh) and a reduction in open-circuit voltage (Voc).

• Characteristics: Closely related to module encapsulation materials (glass, EVA) and cell passivation layers (SiNx). Exhibits rapid decay (hours to days) and partial reversibility (Na+ can be expelled by reverse bias or elevated temperatures).

5. TC (Temperature Cycle)

• Cause: Extreme temperature cycling (-40°C to +85°C).

• Mechanism: Differences in thermal expansion coefficients among materials (glass, EVA, silicon wafers, solder ribbons) generate mechanical stress under cyclic temperature variations. This leads to solder ribbon fatigue fracture, hidden cracks in solar cells, and encapsulation layer delamination (EVA separation), ultimately affecting electrical performance (increased series resistance Rs).

• Characteristics: Evaluates module mechanical reliability; irreversible; primarily impacts physical structure rather than carrier lifetime.

6.DH (Damp Heat Test)

• Causative Factors: High temperature and humidity (85°C/85%RH).

• Mechanism: Combined action of water and heat accelerates material degradation: EVA hydrolysis produces acidic substances that corrode grid lines; aging and cracking of backsheets (e.g., TPT) allow moisture ingress; passivation layers (SiNx) lose effectiveness due to moisture absorption, ultimately causing reductions in fill factor (FF) and open-circuit voltage (Voc).

•Characteristics: Evaluates material weather resistance; irreversible; primarily impacts chemical stability (e.g., corrosion, hydrolysis).

7. UV (Ultraviolet Radiation, UV Aging Test)

• Cause: Ultraviolet light (UV-A/B bands, 280-400nm).

• Mechanism: UV photon energy disrupts molecular chains in encapsulation materials (e.g., EVA ester bond cleavage, Si-N bond oxidation in SiNx), causing EVA yellowing (reduced light transmittance), backsheet embrittlement, and passivation layer failure. This ultimately impacts short-circuit current (Isc) and efficiency.

• Characteristics: Targets photochemical aging; irreversible; primarily affects optical properties and material stability.